Advanced Shipment Notice (ASN)

What is Advanced Shipment Notice (ASN)?[1]

An Advanced Shipping Notice (ASN) is an electronic notification of an upcoming delivery that is sent directly from a supplier or third-party logistics company to a buyer, in advance of the shipment. The content of the ASN depends on the trading partners’ requirements, but typically includes:

- Order information

- Delivery Date and Time

- Location Information

- Pallet Codes

- Product Details

- Physical Characteristics of the Delivery, such as the Type of Packaging, and

- Information about the Carrier

ASNs are typically transmitted in EDI format – either as an ANSI X.12 856 or the EDIFACT DESADV document. Once received by a retailer, the ASNs are uploaded into their Warehouse Management System (WMS). When a shipment arrives, receiving personnel scans the barcode affixed to the pallet of goods. The barcode provides a unique shipment identifier that can be correlated with the records in the WMS. As a result, the receiving personnel can instantly identify the shipment supplier, associated purchase order, expected contents, and its next destination. The overall result is a significant reduction in the receiving time for inbound deliveries.[2]

Functions of Advance Shipment Notice (ASN)[3]

- The ASN serves multiple purposes. When the order is sent to a warehouse, distribution center, or store, it gives an estimated shipment arrival time. Once the shipment arrives at the store, DC, or warehouse, it allows for receiving the shipment through barcode scanning, resulting in quicker unloading and sorting. It can be used to help prepare for flow-through or store allocation from the receiving dock to the shipping dock and out to the store or customer. When the item is being shipped directly to a consumer, it typically offers shipment information, such as a tracking number for FedEx, UPS, or USPS. Last but not least, it can be used to finalize the collection of funds from the consumer’s credit card. That’s a lot of info and functions wrapped up in one document.

- The ASN is more than just a confirmation of “your shipment is on its way,” it’s also a resource and time saver. ASNs can be particularly helpful when it comes to unloading trucks and managing inventory. Before the shipment is sent, suppliers can place bar codes on all their boxes, crates, and cases, and include that information with the ASN. When the shipment arrives, the data from the EDI can be used to ensure the delivery of each piece. The process is as simple as scanning items as they come off the truck, confirming that everything is where it should be. The ASN also makes it easy to identify differences between what was expected, and what was actually shipped.

- Retailers that practice just-in-time inventory pretty much needs the ASN to do that properly. You order just as many products as you need, just when you need them. An ASN can help you know when you’re getting the shipment of items, or if your product has been delayed.

- If a retailer and a vendor are both on electronic data interchange (EDI) systems, this transmission of information can all happen automatically, and without any faxing, emailing, or manually entering orders into the system. Without the ASN, the retailer might not know whether the vendor is going to ship the right quantity or when it will arrive. Without an EDI system, even with an ASN the right people may not be getting the right shipment information at the right time, or human error may cause the data to be manually input incorrectly.

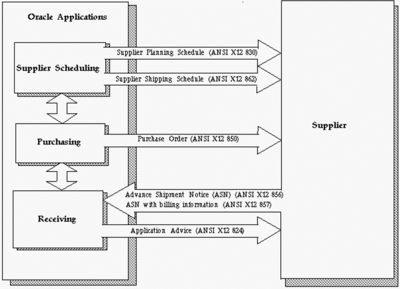

ASN Process (See Figure Below)[4]

The ASN process, shown in the figure below, includes the following:

- A shipment authorization is made to the supplier in the form of a Purchase Order, Planning Schedule, or Shipping Schedule.

- The supplier sends the ASN to the receiving organization at the time of shipment.

- The ASN is verified in the Receiving Open Interface. Intransit and purchasing supplies are updated for ASN lines that are successfully validated. For each accepted line on the ASN, in transit supply is increased, and purchasing supply is reduced. If the data isn't accepted or if there is an error or discrepancy in the data, an Application Advice, containing the most likely cause of the error, is sent to the supplier. The supplier can then send a corrected (New) ASN.

- The goods arrive. You can use the ASN in the Receipts window to create receipts.

- Shipment-vs.-receipt quantities are compared during the receipt transaction process. (As an optional step, CUM quantities can be compared if Oracle Supplier Scheduling is installed.) If discrepancies are detected in shipment-vs.-receipt or CUM quantity comparisons, an Application Advice is sent to the supplier.

Advanced Shipment Notice (ASN) - Best Practices[5]

These best practices have been aggregated from retailers and proven to be "best in class" and are recommended for all retailers. Examples of "best in class" policies and procedures follow. Written policies should be established for receiving personnel either at the store or dc/warehouse level. Written policies should also be established and distributed to suppliers.

- Store level

- Do not allow deliveries to front doors or any other non-authorized doors.

- Differentiate personnel with receiving responsibility from those with merchandising responsibility. Create a distinct line in the receiving area that only authorized inventory receivers can cross.

- Establish an outside time limit for receiving direct store deliveries into your inventory system (no more than 24 hours from the time of delivery).

- New release products should be received immediately.

- No products should be brought to the sales floor prior to being received.

- Establish policies regarding receiving incomplete POs and responding to internal requests for receiving paperwork.

- ASN/UCC-128 shipments should be received from regular direct store deliveries and should be carton received.

- Suppliers should be certified in order for their deliveries to be carton received.

- Establish policies for handling UCC-128 barcodes that can't be read and for receiving "closed" purchase orders or substitutions.

- Warehouse/DC

- Require appointments, and confirm once scheduled.

- Require the Shipment Status Message (EDI 214) from carriers and the Advance Ship Notice (EDI 856) in advance of delivery.

- To receive products, scan cartons and create and apply internal pick labels.

- Receiving direct store deliveries (Overall Process)

- Ensure accurate receiving and record-keeping of all Direct Store Deliveries by observing the following:

- Accept all Direct Store Deliveries at the warehouse doors only. (Note: Do not allow carriers to deliver shipments to the front doors)

- The team responsible for receiving must receive direct store deliveries into the inventory system within 24 hours of product arrival at the store and before bringing the product to the sales floor.

- All new-release products must be received immediately.

- Ensure there is a distinct line in the receiving area that only authorized inventory receivers can cross.

- After the appropriate team receives a direct store delivery into your inventory system, the merchandising team transports the products to the sales floor and merchandises them.

- If a merchandising team member is not available, store the products in the warehouse.

- When business permits, merchandising team members check the warehouse for shipments to be merchandised, transport these products to the sales floor, and merchandise them as appropriate.

- If all items on a direct store delivery Purchase Order (PO) do not arrive, wait 72 hours before claiming a loss in order to account for a product still being shipped to the store.

- If your company's accounting department or inventory control department request receiving paperwork fulfills the request within three business days to reduce discrepancies that result in store shrink.

- Complete all additional, required procedures for each type of Drop Shipment as outlined below.

See Also

References