Kanban

Kanban is one of the approaches for Agile Implementation, which was first used and developed by Taiichi Ohno. Taiichi Ohno was working as an Industrial Engineer at the Japanese company Toyota. It is an approach which uses a visual system for managing the work as it moves forward. While Taiichi Ohno developed it for the manufacturing work, it was not until 2004 when David J. Anderson used this method for the IT Software Development, and since then, it has become one of the most popular agile development approaches.[1]

Types of Kanban Systems[2]

In a Kanban system, adjacent upstream and downstream workstations communicate with each other through their cards, where each container has a Kanban associated with it. Economic Order Quantity is important. The two most important types of Kansans are:

- Production (P) Kanban: A P-Kanban, when received, authorizes the workstation to produce a fixed amount of products. The P-Kanban is carried on the containers that are associated with it.

- Transportation (T) Kanban: A T-Kanban authorizes the transportation of the full container to the downstream workstation. The T-Kanban is also carried on the containers that are associated with the transportation to move through the loop again.

The Kanban philosophy and Task Boards are also used in Agile project management to coordinate tasks in project teams. An online demonstration can be seen in an Agile Simulator.

Implementation of Kanban can be described in the following manner:

- The workflow consists of logical steps.

- There are two steps to a workflow viz. queue and work in progress/process.

- The team in charge decides on the maximum amount of work each step of the workflow can hold.

- Work is pushed into the queue step and pulled into the process step.

- If need be, work is halted in two successive stages to clear bottleneck.

Kanbrain

A third type involves corporate training. Following the just-in-time principle, computer-based training permits those who need to learn a skill to do so when the need arises, rather than take courses and lose the effectiveness of what they've learned from lack of practice.

Electronic Kanban

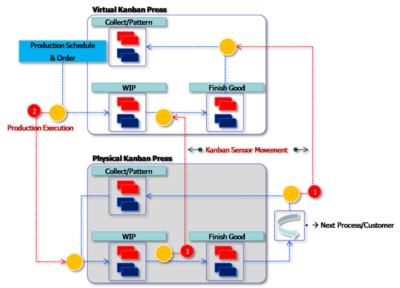

Many manufacturers have implemented electronic Kanban (sometimes referred to as e-Kanban) systems. These help to eliminate common problems such as manual entry errors and lost cards. E-Kanban systems can be integrated into enterprise resource planning (ERP) systems, enabling real-time demand signaling across the supply chain and improved visibility. Data pulled from E-Kanban systems can be used to optimize inventory levels by better tracking supplier lead and replenishment times.

E-Kanban is a signaling system that uses a mix of technology to trigger the movement of materials within a manufacturing or production facility. Electronic Kanban differs from traditional Kanban in using technology to replace traditional elements like Kanban cards with barcodes and electronic messages like email or Electronic data interchange.

A typical electronic Kanban system marks inventory with barcodes, which workers scan at various stages of the manufacturing process to signal usage. The scans relay messages to internal/external stores to ensure the restocking of products. Electronic Kanban often uses the internet as a method of routing messages to external suppliers and as a means to allow a real-time view of inventory, via a portal, throughout the supply chain.

Organizations like the Ford Motor Company and Bombardier Aerospace have used electronic Kanban systems to improve processes. Systems are now widespread from single solutions or bolt on modules to ERP systems.

Kanban Board[3]

A Kanban board is a tool for workflow visualization and a key component of the Kanban method. Visualizing your workflow and tasks on a Kanban board helps you better understand your processes and gain an overview of your workload.