Difference between revisions of "Product Lifecycle Management"

(Product lifecycle management, sometimes "product life cycle management", represents an all-encompassing vision for managing all data relating to the design, production, support and ultimate disposal of manufactured goods.) |

|||

| Line 34: | Line 34: | ||

[[File:PLM.png|400px|Product Lifecycle Management]]<br /> | [[File:PLM.png|400px|Product Lifecycle Management]]<br /> | ||

source: [https://en.wikipedia.org/wiki/Product_lifecycl |Wikipedia] | source: [https://en.wikipedia.org/wiki/Product_lifecycl |Wikipedia] | ||

| + | |||

| + | |||

| + | == PLM & ERP<ref>PLM Vs. ERP [https://www.batchmaster.co.in/blog/a-brief-guide-on-product-lifecycle-management/ BatchMaster]</ref> == | ||

| + | An ERP and a PLM system go well together, acting as collaborative tools that can communicate with each other and support the various distinct needs of a business. The basic difference between the two interchangeable systems lies in the names; while PLM is product-specific, more focused on the creation of a product or the product line in particular, ERP is enterprise-specific and has a broader scope, which involves gathering information and tracking a business’s resources throughout a year/cycle. PLM focuses on managing the development of the product, while ERP intends to manage the resource planning for production. A PLM system stores the initial product data such as product design, and once it is ready to be produced, the ERP system, integrated with the PLM, comes into play in order to manage the resources. According to a CIM Data report, a PLM—ERP integration across the enterprise can result in: | ||

| + | *75% reduction in terms of time, cost, and efforts associated with entering data from one system to the other. | ||

| + | *75% reduction in the BOM-error cost, since BOMs are created only once and then managed consistently across both the PLM and ERP systems. | ||

| + | *15% reduction in inventory cost, since designers and engineers are aware of which components are already on hand. | ||

| + | *An 8% reduction in scrap generated. | ||

| + | Since PLM manages product development, and ERP aims to manage the resource planning for production, it only makes sense to use these tools in sequential order. But if the sequence is not followed and ERP software is implemented before a PLM, the risk of submitting inaccurate product data to an ERP system, inefficient spending, product recalls, and violating compliance regulations gets high. By integrating ERP software with PLM, the most up-to-date product data is available at any time and can be shared with the necessary departments to ensure accurate financial planning. Thus, both an ERP system, and a PLM system, are critical components in a company’s growth and ability to innovate. | ||

Revision as of 14:39, 9 September 2019

Product lifecycle management, sometimes "product life cycle management", represents an all-encompassing vision for managing all data relating to the design, production, support and ultimate disposal of manufactured goods. PLM concepts were first introduced where safety and control have been extremely important, notably the aerospace, medical device, military and nuclear industries. These industries originated the discipline of configuration management (CM), which evolved into electronic data management systems (EDMS), which then further evolved to product data management (PDM). Over the last ten years, manufacturers of instrumentation, industrial machinery, consumer electronics, packaged goods and other complex engineered products have discovered the benefits of PLM solutions and are adopting efficient PLM software in increasing numbers.[1]

Introduction to PLM Development Process[2]

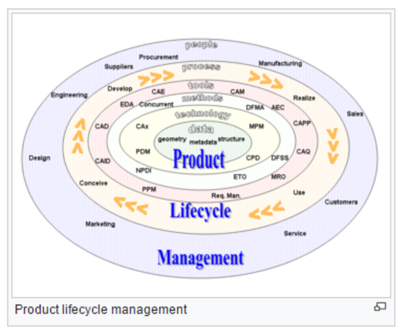

The core of PLM (product lifecycle management) is in the creation and central management of all product data and the technology used to access this information and knowledge. PLM as a discipline emerged from tools such as CAD, CAM and PDM, but can be viewed as the integration of these tools with methods, people and the processes through all stages of a product’s life. It is not just about software technology but is also a business strategy

For simplicity the stages described are shown in a traditional sequential engineering workflow ( see figure below). The exact order of event and tasks will vary according to the product and industry in question but the main processes are:

- Conceive

- Specification

- Concept design

- Design

- Validation and analysis (simulation)

- Tool design

- Realise

- Plan manufacturing

- Manufacture

- Build/Assemble

- Test (quality control)

- Service

- Sell and deliver

- Use

- Maintain and support

- Dispose

The major key point events are:

- Order

- Idea

- Kickoff

- Design freeze

- Launch

The reality is however more complex, people and departments cannot perform their tasks in isolation and one activity cannot simply finish and the next activity start. Design is an iterative process, often designs need to be modified due to manufacturing constraints or conflicting requirements. Whether a customer order fits into the time line depends on the industry type and whether the products are for example, built to order, engineered to order, or assembled to order.

source: |Wikipedia

PLM & ERP[3]

An ERP and a PLM system go well together, acting as collaborative tools that can communicate with each other and support the various distinct needs of a business. The basic difference between the two interchangeable systems lies in the names; while PLM is product-specific, more focused on the creation of a product or the product line in particular, ERP is enterprise-specific and has a broader scope, which involves gathering information and tracking a business’s resources throughout a year/cycle. PLM focuses on managing the development of the product, while ERP intends to manage the resource planning for production. A PLM system stores the initial product data such as product design, and once it is ready to be produced, the ERP system, integrated with the PLM, comes into play in order to manage the resources. According to a CIM Data report, a PLM—ERP integration across the enterprise can result in:

- 75% reduction in terms of time, cost, and efforts associated with entering data from one system to the other.

- 75% reduction in the BOM-error cost, since BOMs are created only once and then managed consistently across both the PLM and ERP systems.

- 15% reduction in inventory cost, since designers and engineers are aware of which components are already on hand.

- An 8% reduction in scrap generated.

Since PLM manages product development, and ERP aims to manage the resource planning for production, it only makes sense to use these tools in sequential order. But if the sequence is not followed and ERP software is implemented before a PLM, the risk of submitting inaccurate product data to an ERP system, inefficient spending, product recalls, and violating compliance regulations gets high. By integrating ERP software with PLM, the most up-to-date product data is available at any time and can be shared with the necessary departments to ensure accurate financial planning. Thus, both an ERP system, and a PLM system, are critical components in a company’s growth and ability to innovate.

References