Difference between revisions of "Product Lifecycle Management"

| Line 1: | Line 1: | ||

| − | |||

| − | + | == Definition of Product Lifecycle Management (PLM) == | |

| + | In Industry, Product Lifecycle Management is the process of managing the entire lifecycle of a product from inception, through engineering design and manufacture, to service and disposal of manufactured products. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprise.<ref>Defining Product Lifecycle Management (PLM) [https://global-value-web.com/product-lifecycle-management.html Global Value Web]</ref> | ||

| + | |||

| + | |||

| + | [[File:PLM.png|400px|Product Lifecycle Management]]<br /> | ||

| + | source: Global Value Web | ||

| + | |||

| + | |||

| + | Product lifecycle management, sometimes "product life cycle management", represents an all-encompassing vision for managing all data relating to the design, production, support and ultimate disposal of manufactured goods. PLM concepts were first introduced where safety and control have been extremely important, notably the aerospace, medical device, military and nuclear industries. These industries originated the discipline of [[Configuration_Management_(CM)|configuration management (CM)]], which evolved into electronic data management systems (EDMS), which then further evolved to [[Product Data Management (PDM)|product data management (PDM)]]. Over the last ten years, manufacturers of instrumentation, industrial machinery, consumer electronics, packaged goods and other complex engineered products have discovered the benefits of PLM solutions and are adopting efficient PLM software in increasing numbers.<ref>Explaining Product lifecycle management [http://www.product-lifecycle-management.com/ PLM]</ref> | ||

| + | |||

| + | |||

| + | == A History of Product Lifecycle Management (PLM)<ref>History of Product Lifecycle Management (PLM) [https://www.investopedia.com/terms/p/product-life-cycle-management.asp Investopedia]</ref> == | ||

| + | The concept of a product having stages of life (and the need to manage them) arose as early as 1931. Around 1957, an employee of Booz, Allen and Hamilton, the advertising agency, theorized a five-step life cycle for goods, beginning with the introduction phase, rising through growth and maturity, and eventually hitting saturation and decline. | ||

| + | |||

| + | Eventually, PLM developed as a manufacturing and marketing tool for businesses seeking to maximize the advantage of bringing new products to the market first. | ||

| + | |||

| + | One of the first recorded applications of modern PLM occurred with American Motors Corporation (AMC) in 1985. Looking for a way to speed up its product development process to better compete against its larger competitors in 1985—while lacking their larger budgets—AMC decided to place emphasis on bolstering the product lifecycle of its prime products (particularly Jeeps). Following that strategy, after introducing its compact Jeep Cherokee, the vehicle that launched the modern sport utility vehicle (SUV) market, AMC began development of a new model, that eventually debuted as the Jeep Grand Cherokee. | ||

| + | |||

| + | |||

| + | == The Essential Elements of PLM<ref>The essential elements of PLM - PLM solutions [https://www.product-lifecycle-management.com/ Product Lifecycle Management dot com]</ref> == | ||

| + | PLM can be thought of as both (a) a repository for all information that affects a product, and (b) a communication process between product stakeholders: principally marketing, engineering, manufacturing and field service. The PLM system is the first place where all product information from marketing and design comes together, and where it leaves in a form suitable for production and support. A few analysts use "PLM" as an umbrella term that includes engineering CAD (for "information authoring"). But product information creation tools include word processors; spreadsheet and graphics programs; requirements analysis and market assessment tools; field trouble reports; and even emails or other correspondence. In our view, a PLM tool focuses exclusively on managing data that covers the breadth of a product's lifecycle, without regard to how that data is developed. The essential elements of PLM: | ||

| + | *Manages design and process documents | ||

| + | *Constructs and controls bill of material (product structure) records | ||

| + | *Offers an electronic file repository | ||

| + | *Includes built-in and custom part and document metadata ("attributes") | ||

| + | *Identifies materials content for environmental compliance | ||

| + | *Permits item-focused task assignments | ||

| + | *Enables workflow and process management for approving changes | ||

| + | *Controls multi-user secured access, including "electronic signature" | ||

| + | *Exports data for downstream ERP systems | ||

| + | |||

| + | |||

| + | == The PLM Development Process == | ||

The core of PLM (product lifecycle management) is in the creation and central management of all product data and the technology used to access this information and knowledge. PLM as a discipline emerged from tools such as CAD, CAM and PDM, but can be viewed as the integration of these tools with methods, people and the processes through all stages of a product’s life. It is not just about software technology but is also a business strategy | The core of PLM (product lifecycle management) is in the creation and central management of all product data and the technology used to access this information and knowledge. PLM as a discipline emerged from tools such as CAD, CAM and PDM, but can be viewed as the integration of these tools with methods, people and the processes through all stages of a product’s life. It is not just about software technology but is also a business strategy | ||

| Line 29: | Line 60: | ||

*Launch | *Launch | ||

| − | The reality is however more complex, people and departments cannot perform their tasks in isolation and one activity cannot simply finish and the next activity start. Design is an iterative process, often designs need to be modified due to manufacturing constraints or conflicting requirements. Whether a customer order fits into the time line depends on the industry type and whether the products are for example, built to order, engineered to order, or assembled to order. | + | The reality is however more complex, people and departments cannot perform their tasks in isolation and one activity cannot simply finish and the next activity start. Design is an iterative process, often designs need to be modified due to manufacturing constraints or conflicting requirements. Whether a customer order fits into the time line depends on the industry type and whether the products are for example, built to order, engineered to order, or assembled to order.<ref>Introduction to PLM Development Process [https://en.wikipedia.org/wiki/Product_lifecycle Wikipedia]</ref> |

| + | |||

| + | Proper tool implementation ensures that the data which is critical for product development is controlled, and accessible throughout the product lifecycle. PLM is an overall business integration approach providing an end-to-end solution to close the loop between design process and product support. The PLM environment provides a common operating platform enabling multiple departments within the enterprise to work with the same data concurrently. Product developers retain rapid-fielding capabilities and cross-platform compatibility while in-service support maintainers acquire the most up-to-date product information. | ||

| + | |||

| + | As [[Additive Manufacturing (AM)]] becomes part of the supply chain, there will be new processes and data types to incorporate. These processes can be documented and actualized within any of the PLM tools. Standards for AM are still being developed, and can encompass much more than just part geometry. Establishing an environment that ties modeling, simulation, and all manufacturing data into the AM process enables the enterprise to build a better understanding of the technology and feasibility for widespread application. PLM systems can incorporate processes and capture the data that constitutes the digital thread of NAVAIR systems. The implementation will support a consolidated single source of authenticated information that can be tied into many tools and shared with other IT systems. It is important to evaluate the best overall data management environment, not just what appears to be the cheapest PLM license cost. Total cost is heavily dependent on what other software—especially CAD programs—will be accessing and contributing to PLM both through plug-ins and customizations. Custom software interfaces can have significant long-term costs once regular software updates are accounted for. Additionally, utilizing open standards where possible can help reduce cost and risk. The better defined the data to be managed by the PLM, the more accurate the overall pricing estimates will be. | ||

| + | |||

| + | A single PLM tool can combine all of the data that defines a system, assimilating roles and process into an interconnected framework. When placed in the context of major defense systems, these roles and processes can be related as shown:<ref>PLM Process within PLM Tools [https://stracongroup.com/services/product-life-cycle-management/ Stracon]</ref> | ||

| − | [[File: | + | [[File:PLM_Interconnected_Framework.png|400px|PLM Interconnected Framework in the context of major defense systems]]<br /> |

| − | source: [https:// | + | source: Stracon Group |

| + | |||

| + | |||

| + | == The Product Lifecycle Management Stages<ref>what are the Stages Product Life Cycle Management [https://www.smartsheet.com/product-life-cycle-management Smartsheet]</ref> == | ||

| + | |||

| + | Since many companies need to coordinate their resources and people in different places, the processes need to be cohesive if there is a chance at minimizing waste. Cohesiveness also keeps the process product-centric and gives it a better chance of success in the marketplace. Many industry models of PLM are in use today. The one featured below is a compilation of the best and most widespread methods used with the necessary steps annotated. To start, PLM has three overarching stages: | ||

| + | *Beginning of Life (BOL): The beginning of life phase includes all of the design and manufacturing, which consists of the initial conceptualization and development, and any prototypes built. Initial development has multiple sub-actions that identify all the requirements, concepts, and necessary testing. Regardless of the structure of production, the company must maintain the BOL stage. BOL is your product coming to life, along with its specifications, production process, and supply needs. | ||

| + | *Middle of Life (MOL): The middle of life phase is post-manufacturing, when your product is distributed, used, and serviced. At this point, your product is in the hands of the end user. You can collect data on any failures, maintenance rates, and user experience to get information for immediate fixes and future development. | ||

| + | *End of Life (EOL): The end of life phase is the retiring, recycling, or disposing of your product. At this point, the reverse logistics happen for the company. EOL starts when users no longer have a need for the product. At this stage, companies collect information about what parts and materials are still valuable. | ||

| Line 52: | Line 97: | ||

*Product Lifecycle Management Defined [http://www.product-lifecycle-management.info/ PLM] | *Product Lifecycle Management Defined [http://www.product-lifecycle-management.info/ PLM] | ||

*The Business Layer of Product Lifecycle Management (PLM) [https://www.sopheon.com/product-lifecycle-management-plm/ sopheon] | *The Business Layer of Product Lifecycle Management (PLM) [https://www.sopheon.com/product-lifecycle-management-plm/ sopheon] | ||

| + | *Global Product Lifecycle Management (PLM) Software Market: Size, Trends & Forecasts (2018-2022) [https://honestversion.com/product-lifecycle-management-plm-software-market-2019-precise-outlook-autodesk-dassault-systmes-ptc-siemens/ Marketing Insights] | ||

Revision as of 15:23, 9 September 2019

Definition of Product Lifecycle Management (PLM)

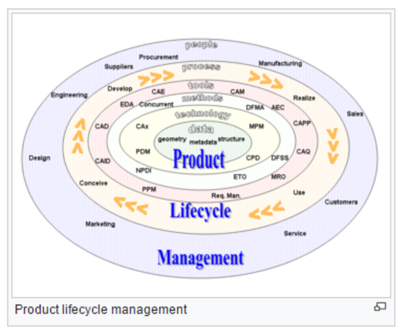

In Industry, Product Lifecycle Management is the process of managing the entire lifecycle of a product from inception, through engineering design and manufacture, to service and disposal of manufactured products. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprise.[1]

Product lifecycle management, sometimes "product life cycle management", represents an all-encompassing vision for managing all data relating to the design, production, support and ultimate disposal of manufactured goods. PLM concepts were first introduced where safety and control have been extremely important, notably the aerospace, medical device, military and nuclear industries. These industries originated the discipline of configuration management (CM), which evolved into electronic data management systems (EDMS), which then further evolved to product data management (PDM). Over the last ten years, manufacturers of instrumentation, industrial machinery, consumer electronics, packaged goods and other complex engineered products have discovered the benefits of PLM solutions and are adopting efficient PLM software in increasing numbers.[2]

A History of Product Lifecycle Management (PLM)[3]

The concept of a product having stages of life (and the need to manage them) arose as early as 1931. Around 1957, an employee of Booz, Allen and Hamilton, the advertising agency, theorized a five-step life cycle for goods, beginning with the introduction phase, rising through growth and maturity, and eventually hitting saturation and decline.

Eventually, PLM developed as a manufacturing and marketing tool for businesses seeking to maximize the advantage of bringing new products to the market first.

One of the first recorded applications of modern PLM occurred with American Motors Corporation (AMC) in 1985. Looking for a way to speed up its product development process to better compete against its larger competitors in 1985—while lacking their larger budgets—AMC decided to place emphasis on bolstering the product lifecycle of its prime products (particularly Jeeps). Following that strategy, after introducing its compact Jeep Cherokee, the vehicle that launched the modern sport utility vehicle (SUV) market, AMC began development of a new model, that eventually debuted as the Jeep Grand Cherokee.

The Essential Elements of PLM[4]

PLM can be thought of as both (a) a repository for all information that affects a product, and (b) a communication process between product stakeholders: principally marketing, engineering, manufacturing and field service. The PLM system is the first place where all product information from marketing and design comes together, and where it leaves in a form suitable for production and support. A few analysts use "PLM" as an umbrella term that includes engineering CAD (for "information authoring"). But product information creation tools include word processors; spreadsheet and graphics programs; requirements analysis and market assessment tools; field trouble reports; and even emails or other correspondence. In our view, a PLM tool focuses exclusively on managing data that covers the breadth of a product's lifecycle, without regard to how that data is developed. The essential elements of PLM:

- Manages design and process documents

- Constructs and controls bill of material (product structure) records

- Offers an electronic file repository

- Includes built-in and custom part and document metadata ("attributes")

- Identifies materials content for environmental compliance

- Permits item-focused task assignments

- Enables workflow and process management for approving changes

- Controls multi-user secured access, including "electronic signature"

- Exports data for downstream ERP systems

The PLM Development Process

The core of PLM (product lifecycle management) is in the creation and central management of all product data and the technology used to access this information and knowledge. PLM as a discipline emerged from tools such as CAD, CAM and PDM, but can be viewed as the integration of these tools with methods, people and the processes through all stages of a product’s life. It is not just about software technology but is also a business strategy

For simplicity the stages described are shown in a traditional sequential engineering workflow ( see figure below). The exact order of event and tasks will vary according to the product and industry in question but the main processes are:

- Conceive

- Specification

- Concept design

- Design

- Validation and analysis (simulation)

- Tool design

- Realise

- Plan manufacturing

- Manufacture

- Build/Assemble

- Test (quality control)

- Service

- Sell and deliver

- Use

- Maintain and support

- Dispose

The major key point events are:

- Order

- Idea

- Kickoff

- Design freeze

- Launch

The reality is however more complex, people and departments cannot perform their tasks in isolation and one activity cannot simply finish and the next activity start. Design is an iterative process, often designs need to be modified due to manufacturing constraints or conflicting requirements. Whether a customer order fits into the time line depends on the industry type and whether the products are for example, built to order, engineered to order, or assembled to order.[5]

Proper tool implementation ensures that the data which is critical for product development is controlled, and accessible throughout the product lifecycle. PLM is an overall business integration approach providing an end-to-end solution to close the loop between design process and product support. The PLM environment provides a common operating platform enabling multiple departments within the enterprise to work with the same data concurrently. Product developers retain rapid-fielding capabilities and cross-platform compatibility while in-service support maintainers acquire the most up-to-date product information.

As Additive Manufacturing (AM) becomes part of the supply chain, there will be new processes and data types to incorporate. These processes can be documented and actualized within any of the PLM tools. Standards for AM are still being developed, and can encompass much more than just part geometry. Establishing an environment that ties modeling, simulation, and all manufacturing data into the AM process enables the enterprise to build a better understanding of the technology and feasibility for widespread application. PLM systems can incorporate processes and capture the data that constitutes the digital thread of NAVAIR systems. The implementation will support a consolidated single source of authenticated information that can be tied into many tools and shared with other IT systems. It is important to evaluate the best overall data management environment, not just what appears to be the cheapest PLM license cost. Total cost is heavily dependent on what other software—especially CAD programs—will be accessing and contributing to PLM both through plug-ins and customizations. Custom software interfaces can have significant long-term costs once regular software updates are accounted for. Additionally, utilizing open standards where possible can help reduce cost and risk. The better defined the data to be managed by the PLM, the more accurate the overall pricing estimates will be.

A single PLM tool can combine all of the data that defines a system, assimilating roles and process into an interconnected framework. When placed in the context of major defense systems, these roles and processes can be related as shown:[6]

The Product Lifecycle Management Stages[7]

Since many companies need to coordinate their resources and people in different places, the processes need to be cohesive if there is a chance at minimizing waste. Cohesiveness also keeps the process product-centric and gives it a better chance of success in the marketplace. Many industry models of PLM are in use today. The one featured below is a compilation of the best and most widespread methods used with the necessary steps annotated. To start, PLM has three overarching stages:

- Beginning of Life (BOL): The beginning of life phase includes all of the design and manufacturing, which consists of the initial conceptualization and development, and any prototypes built. Initial development has multiple sub-actions that identify all the requirements, concepts, and necessary testing. Regardless of the structure of production, the company must maintain the BOL stage. BOL is your product coming to life, along with its specifications, production process, and supply needs.

- Middle of Life (MOL): The middle of life phase is post-manufacturing, when your product is distributed, used, and serviced. At this point, your product is in the hands of the end user. You can collect data on any failures, maintenance rates, and user experience to get information for immediate fixes and future development.

- End of Life (EOL): The end of life phase is the retiring, recycling, or disposing of your product. At this point, the reverse logistics happen for the company. EOL starts when users no longer have a need for the product. At this stage, companies collect information about what parts and materials are still valuable.

PLM & ERP[8]

An ERP and a PLM system go well together, acting as collaborative tools that can communicate with each other and support the various distinct needs of a business. The basic difference between the two interchangeable systems lies in the names; while PLM is product-specific, more focused on the creation of a product or the product line in particular, ERP is enterprise-specific and has a broader scope, which involves gathering information and tracking a business’s resources throughout a year/cycle. PLM focuses on managing the development of the product, while ERP intends to manage the resource planning for production. A PLM system stores the initial product data such as product design, and once it is ready to be produced, the ERP system, integrated with the PLM, comes into play in order to manage the resources. According to a CIM Data report, a PLM—ERP integration across the enterprise can result in:

- 75% reduction in terms of time, cost, and efforts associated with entering data from one system to the other.

- 75% reduction in the BOM-error cost, since BOMs are created only once and then managed consistently across both the PLM and ERP systems.

- 15% reduction in inventory cost, since designers and engineers are aware of which components are already on hand.

- An 8% reduction in scrap generated.

Since PLM manages product development, and ERP aims to manage the resource planning for production, it only makes sense to use these tools in sequential order. But if the sequence is not followed and ERP software is implemented before a PLM, the risk of submitting inaccurate product data to an ERP system, inefficient spending, product recalls, and violating compliance regulations gets high. By integrating ERP software with PLM, the most up-to-date product data is available at any time and can be shared with the necessary departments to ensure accurate financial planning. Thus, both an ERP system, and a PLM system, are critical components in a company’s growth and ability to innovate.

References

- ↑ Defining Product Lifecycle Management (PLM) Global Value Web

- ↑ Explaining Product lifecycle management PLM

- ↑ History of Product Lifecycle Management (PLM) Investopedia

- ↑ The essential elements of PLM - PLM solutions Product Lifecycle Management dot com

- ↑ Introduction to PLM Development Process Wikipedia

- ↑ PLM Process within PLM Tools Stracon

- ↑ what are the Stages Product Life Cycle Management Smartsheet

- ↑ PLM Vs. ERP BatchMaster

Further Reading

- Product Lifecycle Management Defined PLM

- The Business Layer of Product Lifecycle Management (PLM) sopheon

- Global Product Lifecycle Management (PLM) Software Market: Size, Trends & Forecasts (2018-2022) Marketing Insights