ABC Analysis

ABC Analysis is defined in the Business Dictionary as "An analysis of a range of items that have different levels of significance and should be handled or controlled differently. It is a form of Pareto analysis in which the items (such as activities, customers, documents, inventory items, and sales territories) are grouped into three categories (A, B, and C) in order of their estimated importance. 'A' items are very important, 'B' items are important, 'C' items are marginally important. For example, the best customers who yield the highest revenue are given the 'A' rating, are usually serviced by the sales manager, and receive the most attention. 'B' and 'C' customers warrant progressively less attention and are serviced accordingly."[1]

Extensively used for Supply Chain Management (SCM), inventory systems, and stock checking methods, ABC analysis is often applied to the design of cycle counting systems. For example, a warehouse or factory store might choose to count A items, of high worth once a quarter, but B items only two times a year with C items only counted once. From an optimization point of view, companies looking to drive down working capital and carrying costs should be analyzing inventory far more frequently as these industry averages leave the door open for large quantities of excess stock and obsolete stock to pile up in warehouses. Unfortunately, most wholesale distributors and manufacturers do not put this into practice and as a result, have a large percentage of working capital tied up in unhealthy inventory levels. Stock checking and tighter control of higher value items not only help to maintain a better idea of the value of assets being held at any one time but also assists with reordering, whereby reorder points for the different classes are handled with their own controls, with perhaps less high-value items being held in stock at any one time and more frequent reordering of them done to compensate. Likewise, slow-moving category C items should not usually be re-ordered with the same frequency as B items because money will be tied up in stock as a result. Performing ABC analysis helps both wholesalers and distributors to identify which items should be brought into stock – and when – so that customer demands can be met whilst maintaining a healthy balance sheet.[2]

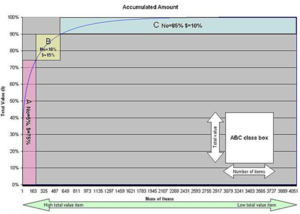

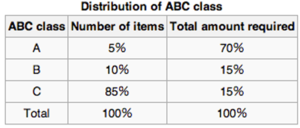

The following is an example of the Application of Weighed Operation based on ABC class in electronics manufacturing company with 4,051 active parts.

source: boundless

Using this distribution of ABC class and change the total number of the parts to 4,000.

source: [1]

See Also

References