Advanced Distribution Management Systems (ADMS)

What is Advanced Distribution Management Systems (ADMS)?[1]

An advanced distribution management system (ADMS) is a software platform that supports the full suite of distribution management and optimization. An ADMS includes functions that automate outage restoration and optimize the performance of the distribution grid. ADMS functions being developed for electric utilities include fault location, isolation, and restoration; volt/volt-ampere reactive optimization; conservation through voltage reduction; peak demand management; and support for microgrids and electric vehicles.

ADMS (Advanced Distribution Management System) is the next level of software sophistication to accomplish modern goals. ADMS is a single software platform inclusive of SCADA, OMS, and DMS. It has the functionality of DMS and OMS applications and utilizes the real-time data acquisition capabilities of SCADA to accentuate each system’s capabilities. All of this data is then visually represented and managed from a single, intuitive graphical user interface. With the new generation of utility employees just around the corner, the expectation to become proficient and manage all of these systems (i.e. OMS, DMS, and SCADA) will naturally become complex. Furthermore, the responsibility of a distribution operator is already escalating. He/she is now required to manage distributed generation resources, decrease outage times, reduce feeder burden, and improve circuit performance and efficiency all at once. The best response to this complexity is simplicity. One integrated platform eliminates the need for a single employee to be responsible for multiple software and servers and has to attend training to manage/troubleshoot all of them. A single ADMS simplifies operating tasks and eliminates the need to maintain and coordinate multiple operating models. Interoperability is another important goal to bring comprehensive data into one platform. Industry standards such as MultiSpeak are important to transfer data such as AMI or GIS seamlessly from other systems. Vendors should be expected to integrate well with other systems through Multispeak or developed interfaces as well. A quick use case will help illustrate the simplicity and efficiency of an ADMS system. If a pole was knocked over by a car, a DMS application like FDIR (Fault Detection Isolation Restoration), with the help of real-time SCADA information, would identify the fault location, isolate the location and restore power to as many consumers as possible. The OMS capabilities in the ADMS system will continue to locate the nearest truck to dispatch to the location. The ADMS can then proceed to create switching orders for the field personnel to perform restorations. While ADMS is facilitating the outage, the system can concurrently engage consumers of the outage situation through the use of web portals or even Facebook or Twitter notifications.[2]

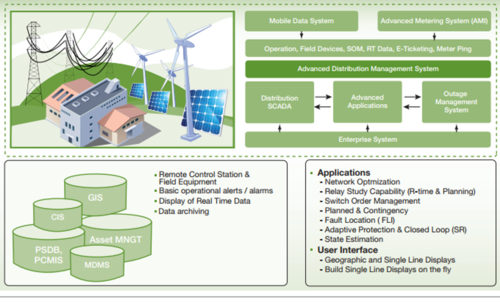

Major ADMS Components (see figure below)[3]

- Control System: The ADMS typically includes a SCADA system, an OMS, and advanced applications.

- Data: The ADMS needs information to realize the full potential of its function. Data is obtained from intelligent field devices and enterprise systems. In addition, AMI networks can provide the last gasp information to enhance outage management processing within ADMS as well as the capability to perform outbound meter pings to test for voltage potential at the meter base endpoint.

- Mobility: Mobile systems can be used to directly view and operate the network on field tablets or mobile data terminals. Outage Management Systems get enhanced capabilities through mobility by providing e-ticketing for crew dispatch and tracking, occurrence/cause/repair reporting, and up-to-date customer outage information.

- Advanced Applications: The following is a brief description of available advanced applications. What’s important is to understand the applications, know the key business drivers and ensure the solution you are selecting has the functionality to successfully meet your utility’s objectives.

- Relay Protection Analysis, Adaptive Protection, Closed Loop: These applications are very closely linked. First, the relay protection analysis application performs analytical studies on the network. When supplemented by adaptive protection your system can determine the correct relay setting to support new configurations. Once the new configuration is known with a closed-loop application, the system will automatically reconfigure without the need for operator intervention. By providing the tools to the individuals who manage the system, in real-time you receive:

- Improvement in your reliability indices – SAIDI, CAIDI

- Improvement in your operation effectiveness – a significant reduction in the number of studies required by supporting technical staff

- State Estimation: State Estimation calculates results based on available telemetry points and customer load profile information. The more telemetry points on the system the greater the accuracy of the state estimation. The application should be considered the enabler of other applications. Several other applications use state-estimated values such as load flow analysis, relay protection analysis, and volt var optimization just to name a few.

- Switch Order Management: The Switch Order Management application provides the user with the option to create switching orders either manually or automatically. The application allows the user to customize the switching order to reflect current in-house templates. The business benefit is that all relevant factors are being analyzed on a single platform providing improved safety, reliability, and operating effectiveness.

- Fault Location Isolation Service Restoration (FLISR): This application enhances the Fault Location process. Customer restoration is improved by having better information and the ability to direct field crews more accurately to the faulted location. Using information obtained from the relay IED and fault detectors' location in the field will avoid lengthy line patrols and sectionalizing efforts. Some DMS solutions also provide a means whereby data administrators can input historical failures for the feeder in the application. This historical information can be used as one of the mechanisms for determining faulted locations as well. The Isolation and Service Restoration piece of FLISR is the next step. Once the faulted section is known, remotely controlled devices can restore customer load either manually (via remote control) or automatically (without operator intervention). The business benefits include improved field resource utilization, reduced customer interruptions, and less “windshield time” for field forces.

- Network Reconfiguration: This application determines the optimum normal open points on the network to minimize line losses, and provide optimum phase balancing while maintaining adequate voltage profiles. When implemented, this application will develop a list of suggested improvements – new open and closed points on the network. Each step will reflect the net gain if implemented. The business benefit is the optimization of the system by minimizing line losses, and optimum utilization of current assets while gaining workforce efficiency benefits by utilizing the analytics of this DMS application.

- Topology Analyzer: The Topology Analyzer application displays voltages, phasing, and the state of the system (energized or de-energized) using different color schemes as determined by the utility. This application is applicable to single-line schematic displays and geographic displays. Some DMS solutions can create single-line displays on the fly by the user selecting the feeders and/or substations they wish displayed in isolation from other superfluous equipment. From a user perspective, this is very powerful as it provides simplicity and/or clarity for the task at hand. The business benefit is somewhat obvious. Without a method to simplify the electrical connectivity, the visual diagrams would be extremely cluttered and not useful. A lot of work has been done by the vendor community to ensure optimum flexibility is provided for the user.

4 Drivers of ADMS Investments[4]

- Resilience—the ability to withstand or recover from a natural disaster quickly.

- Renewables—the ability to accommodate larger quantities of distributed energy resources.

- Replacement—the ability to supplement legacy systems that are unable to integrate with new technologies and that staff can no longer support.

- Regulation—the ability to accommodate changes that encourage reliability and efficiency.

ADMS Benefits[5]

ADMS provides many important benefits to utility companies:

- Improved Reliability and Resiliency

- Fault Management Processes – manual and automated FLISR seamlessly integrated with OMS to accurately predict incident locations and reduce restoration times

- Network Instability Forecasting – near-term forecasting of load and storm impact, enhanced with historical analysis and integrated weather services.

- Regulatory Compliance – network operation visibility and improved regulatory indices on a secure infrastructure supporting regulatory audits.

- Optimized Network Operations

- Switch Order Management – automated process creating optimal switching steps efficiently validated, via simulation, to reduce outage times and increase operational safety.

- Crew Dispatch – optimized crew dispatch, aligned with forecasted workload and enhanced with AMI integration, mutual aid support, and damage assessment functions.

- Mobile Field Client – using advanced mobile technologies, Field Client includes dashboard, geographic and schematic views, supports both disconnected (off-line) and connected work, switching management, and outage management for improved coordination and resiliency.

- Increased Energy Efficiency and Quality

- Energy Losses – innovative functions for reducing technical and commercial power losses using advanced optimization algorithms Voltage and VAR Profiling **advanced functions for providing the highest quality of power and optimal voltage levels.

- Demand Side Management – supporting various types of demand side management programs allowing optimization of prioritized objectives.

- Reduced Total Cost of Ownership and Capital Investment

- Common Platform – common user experience, data model and structure, integration framework, secure infrastructure, and training simulator for system planning as well as operator training.

- Modular Architecture – ability to deploy individual ADMS components, lowering initial deployment costs and allowing a phased approach, where components can be added as needed, utilizing the same architecture.

- Integration – standards-based CIM integration with external systems such as GIS, AMI, CIS, and Weather Services, etc.

See Also

References