Continuous Process Improvement (CPI)

Continuous Process Improvement is defined as, “The ongoing improvement of products, services or processes through incremental and breakthrough improvements.” It doesn’t only mean that a business should make changes along the way when things aren’t working smoothly. Instead, continuous process improvement is an actual type of work style that is designed to continuously review results and rapidly adopt new measures when deemed necessary. The keyword here is continuous because ultimately broad-scale change and progress stem from small steps along the way that are all geared towards optimization. For some, it may be easy to conflate continuous process improvement as equivalent to other lean methodologies, including Kaizen and Six Sigma, for example. While these frameworks help to improve processes along the way, they can live inside the practice of continuous process improvement, but they are not the same. Two main philosophies exist for continuous process improvement - formalized and adaptive. Formalized continuous process improvement is typically in line with Six Sigma, in which you have a set of techniques that are enacted for a quantifiable financial return. Adaptive continuous process improvement may pull from lean methodologies and approach improving processes on a case-by-case basis.[1]

Continuous Process Improvement (CPI) Model[2]

To do CPI, there are different models or approaches such as Juran Trilogy, PDSA cycle, Kaizen and 5S concept. Here we will discuss four models for continuous improvement, two with their history and basis in manufacturing, and two that are more recent developments.

- Six Sigma: The aim of Six Sigma is to minimize faults, defects and any variation from the established process so as to increase the overall quality of outputs. The term denotes the ratio of faulty products expected per million units, which is 3.4, or to put it another way, a 99.99966% success rate. Six Sigma uses one of two methodologies depending on whether it’s being implemented to improve an existing business process (DMAIC) or create a new one (DFSS). Within these methodologies, a range of quality management tools and workflows are used, including the Five Whys, axiomatic design and cost-benefit analysis. One of the well-known features of Six Sigma is the various roles needed within the organization, including Master Black Belts, who work full-time within a Six Sigma program as in-house coaches, and Champions, who take overall responsibility for the implementation of Six Sigma.

- Kaizen: A Japanese word meaning ‘improvement,’ Kaizen’s ultimate goal is waste elimination. Its origins are in post-WWII Japanese businesses but it now used worldwide. It is an inclusive model of continuous improvement in that opportunities for improvement are expected to be identified by everyone from the CEO downwards – this is unsurprising considering its ubiquity in manufacturing, where front-line workers are often best able to spot inefficiencies in the production cycle. But what this also means is that there’s a distinctive cultural element to Kaizen and the implementation of processes and procedures must work alongside cultural re-alignment to the continuous improvement mindset in order to drive employee suggestions. When Kaizen is used for continuous improvement there are two distinct elements: flow kaizen and process kaizen. The former deals with how information, products and services flow throughout the organization, while the latter focuses on small changes individuals can make quickly to improve efficiency. Kaizen has many principles and makes use of underlying processes that include root cause analysis and PDCA.

- “Fail fast, fail forward”: This is about relentlessly moving towards better solutions by making and learning from mistakes quickly, comfortable that as long as you are going in the right direction failures are simply steps on the path to success. It’s important to understand what it means: it’s not about failing with the big overarching ideas or driving force behind your business, but about tinkering with the small things as you move towards optimal solutions. The phrase has achieved some controversy in recent years, but it’s more the semantics that have come in for criticism rather than the idea. Rob Shelton, global innovation chief at PwC, said that the idea is better represented by a ‘Darwinian engine’ beating at the organization's heart, driving forward repeated testing and dropping of ideas that don’t work. He takes issue with the word ‘fail,’ which has negative connotations, and instead likens the principle to the scientific process: developing a hypothesis, testing, re-hypothesizing and refining. Ultimately this phrase is underpinned by a belief that fearless exploration of new ideas in the right no-blame culture yields innovative results. It’s not about chasing failure but learning experientially.

- Perpetual beta: Perpetual beta represents a mindset and strategy based on the continuous improvement principle that a product, service or solution can never be perfect or completed. It has its origins in software development where the preferred method for delivering software to people has evolved from waiting until it’s as good as possible before shipping it out to customers to shipping a product that is as viable as it needs to be and then, on receipt of constructive feedback, improving it continuously to keep up with the evolving demands of customers. Nowadays the term is used to describe any organization with a product or service that operates with a strong feedback loop between customer and organization, where improvements are made and rolled out quickly, and where the improve/test/review cycle guides how improvements are made.

Principles of Continuous Improvement Model[3]

The continuous improvement model reflects the idea that organizations should undertake incremental improvements to services, products, and processes. It applies to every industry and size of business. Six central principles guide it:

- Principle 1. Improvements are based on small changes rather than major paradigm shifts or new inventions: This concept is essential because significant changes often feel frightening and destabilizing to organizations. By approaching change in small, incremental steps, the continuous improvement model reduces the fear factor and increases speed to improvement. When following this principle, the organization does not need to wait for a strategic shift or a new product release to begin to advance. Any idea that eliminates waste speeds production times, reduces defects, or allows employees to develop new skills, is worth exploring. In addition, this approach opens the door to consider small-scale proposals to improve processes and enable employees to do their best work.

- Principle 2. Employee ideas are valuable: The continuous improvement model relies greatly on employees, not only top management, to identify opportunities for improvement. This bottom-up improvement is effective because employees are closest to the problems and thus better equipped to solve them. When thinking of these two principles, consider the value of engaging your staff. If you ask everyone in the organization for ideas to create a new product line or revolutionize how they care for their patients, you're not going to get anything; staff members are focused on their day-to-day work. They, understandably, can't come up with monumental ideas at the drop of a hat. Instead, ask people what improvement they could make to save them 5 minutes a day. Then empower them to implement that improvement, and spread it to everyone else in the organization doing the same process. In this way, you can take a small idea that anyone could come up with and drive a significant impact. For example, say you get one idea from ten employees, each of which saves them five minutes per day. That's ten ideas. Share all ten of those improvements with one hundred other employees so that every one of them is now saving fifty minutes per day (10 ideas x 5 minutes each). Another way to encourage employees to spot opportunities and implement improvements is to ask, "what bugs you?" Most complaints involve a delta between the current state and the employee's idea of how things should be. Sometimes the gripe includes a specific recommendation. It might go something like, "If they would just do X, Y, and Z, the problem would be solved." Sometimes there is no solution included. You might hear, "There's got to be something they could do to fix this!" Another way to encourage employees to spot opportunities and implement improvements is to ask, "what bugs you?" Leaders who adopt the Continuous Improvement Model do not shy away from employee complaints.

- Principle 3. Incremental improvements are typically inexpensive to implement: Employees tend to focus on small changes that can be accomplished without a lot of expense. In fact, many ideas from employees involve eliminating process steps rather than adding them, which is an excellent way to ensure that every activity adds some value to the customer and reduces wasted effort. Through examining detailed improvement data of a ton of organizations at every stage of the improvement journey around the world, in nearly every industry, KaiNexus discovered that 1.4% of improvement ideas have an impact of over $100,000, and each employee has an average annual impact of $25,000. So, not only are these ideas inexpensive to implement, but they can also have a massive effect on your bottom line.

- Principle 4. Employees take ownership and are involved in improvement: Getting people to change the way they've always done things is hard. Do you know what makes it easier? Rolling out changes that originated from the front lines. When people come up with ideas to improve their own work, they intrinsically see the value of the changes. Knowing that improvements come from their peers inspires faith in the necessity of the changes. By engaging your staff in the continuous improvement model, you empower them to take charge of their own work (but you help them as leaders). As a result, they're able to identify problems or opportunities for improvement, follow through on implementing their ideas, take credit for the work, and see a measurable impact from their efforts. In this way, the sole burden of improvement and process management is lifted from managers, who can spend their time more effectively coaching staff on improvement techniques and removing barriers to implementing changes. Because the continuous improvement model relies on employees for ideas for improvement, they become more invested in the outcome of the change, and employee engagement increases. This increases the chance of successful, sustainable improvement. Improved employee engagement also has a positive impact on retention, customer service, product quality, and recruiting.

- Principle 5. Improvement is reflective: Constant feedback is an essential aspect of the continuous improvement model. During every phase of executing an improvement, open communication is critical to both the final results of the improvement and the maintenance of employee engagement. Admittedly, this is tough to pull off in a traditional improvement culture. Coaches don't have the visibility they need to keep up with everyone doing the improvement work. Senior leaders can't engage without a major time commitment, meetings are tough to schedule, and communication gets buried in inboxes. Organizations with a more modern approach to improvement use continuous improvement software to improve visibility and team collaboration, giving coaches access to the reports they need to evaluate performance and target coaching. Senior leaders can follow the improvements that matter to them and engage quickly and easily. Staff can get the help they need from their managers without having to wait for a meeting or an email. Essentially, continuous improvement software gets everyone on the same page by improving visibility and streamlining communication. Another big advantage of an improvement platform is the ability to broadcast improvement success to the entire organization. When people see others recognized and rewarded for their work, they tend to double down on their own efforts.

- Principle 6. Improvement is measurable and potentially repeatable: It is not enough to simply make a change and call it an improvement. To achieve real success, the impact of change must be measured. This makes it possible to determine if the change can be applied successfully to other problems. Proving positive ROI also helps keep the organization aligned around improvement. Improvement can be measured (most easily with software) in terms of cost savings, revenue, time to market, customer satisfaction, safety incidents, collections, defect reduction, or almost any other key performance indicator for your organization. Making continuous improvement part of company culture is an excellent and cost-effective approach to tackling an organization's most complex challenges. When supported by improvement technology, results can be achieved quickly, and success can be sustained over time.

Steps to Continuous Process Improvement[4]

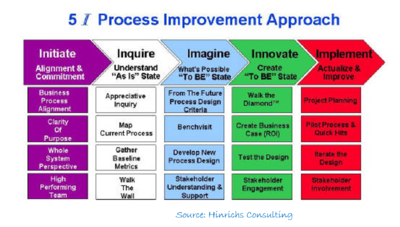

A process improvement methodology, referred to as the “5 I” cycle, provides a sound step by step approach to guide a team to improve a process and provide innovative results. Each step utilizes different tools to achieve the outcomes required at each step. The following is a brief overview of the steps in the process.

- Initiate: Leadership provides clarity for aligned commitment and action to a strategic initiative through a defined project.

- Inquire: Data driven strength based discovery of the “As Is” state and the organization’s roots of success.

- Imagine: Co-creation of the preferred future, the “To Be” state.

- Innovate: Construction of the “To Be” state by designing processes, systems, structures, and culture. It is the creation of the “what” we want. The process changes are made sustainable by "Walking the Diamond". Please click below to see more detail on Walk the Diamond.

- Implement: Engagement and involvement of stakeholders in the strategic projects. Implementation focuses on the “how” we are going to achieve the “what” we want.

Continuous Process Improvement (CPI) Examples[5]

Continuous Improvement is now being practiced in virtually every industry to varying degrees of success. However, certain companies seem to have Continuous Improvement hard-coded into their DNA. These companies appear to have no close competition and still blazing ahead at the speed of light. How do they do it? What makes them tick? What do they all have in common? This article provides 10 Excellent Continuous Improvement Examples for us all to develop a better understanding of what it takes to create a culture of constant growth and innovation.

- Continuous Improvement Examples #1: The Toyota Motor Company: Toyota adopted many of its management practices that we now affectionately term “Lean” from the Ford Motor company, the works of W. Edward Deming, and many other powerful influences of the mid 1900’s. However, Toyota has taken these practices and the application of scientific thinking to new and unimaginable heights, rightfully earning the reputation for being the greatest manufacturing company on earth. The Toyota Production System (TPS) is founded on two primary concepts:

- Jidoka, which means to stop the line whenever a problem occurs to immediately address this issue so that no bad products are produced and

- Just-in-time, which means that each unit of production is made only when the downstream customer or process signals demand for a new unit

All other tools, methods, and principles of TPS stem from these 2 ideals, which Toyota will also admit that it has not perfected. In fact, even Toyota has publicly stated that only 7.5% of everything that it does as a company is value added, calling attention to the fact that even the world’s greatest manufacturer has tons of room for improvement in its quest to eliminate waste.

- Continuous Improvement Examples #2: Amazon.com: Amazon is one of the fastest growing companies on the planet, has been for a long time, and for good reason. The company’s founder, Jeff Bezos, is also listed as the wealthiest human being on the planet and is well on course to be the world’s first trillionaire. Despite the fact that Amazon has come under fire recently for its treatment of employees, especially during the COVID pandemic, you just can’t deny the company’s eCommerce market dominance and showing no signs of slowing down. It doesn’t stop there, Amazon is also quickly closing in on leadership in several other industries such as warehousing, distribution, appliance installation, grocery retail, internet and web services, and so many others.

- What’s the secret to Amazon’s Continuous Improvement sauce?

Step 0 in Continuous Improvement is to become crystal clear on what you’re trying to accomplish. This has to originate from the CEO and be projected down into every decision, especially hiring, firing, and compensation, throughout the organization. Amazon places an undeniable focus on continuously improving the customer and employee experience. In the company’s fulfillment centers, they apply popular CI methods with an emphasis on team-based kaizen events. Jeff Bezos is famous for requiring executives to prepare 6 page memos for meetings, of which PowerPoint decks are strictly prohibited. These memos are then read in silence by meeting participants and before being discussed. This practice reinforces the behavior of fully thinking through the ideas to be discussed and concisely presenting them in as few as 6 pages. It also requires everyone else involved to fully read the document at the start of each meeting, which as you can imagine, cuts down on confusion caused by people coming into the meeting unprepared.

- What’s the secret to Amazon’s Continuous Improvement sauce?

- Continuous Improvement Examples #3: Danaher: Danaher is an innovation company that builds and acquires technologies, operating mainly in the healthcare device manufacturing and service industry. The company has done an incredible job at making Continuous Improvement, via the Danaher Business System (DBS), central to the way it does business. The company’s Continuous Improvement model focuses on systematically driving Leadership, Lean, and Growth. Danaher believes that these three factors gives the company the greatest competitive advantage in both short and long-term operations. The DBS tagline “Common Sense Vigorously Applied,” points to the relentless pursuit the company takes to achieve it’s performance goals via simplified means. Being a publicly traded company, Danaher’s ultimate priority, as openly stated, is to maximize shareholder value. They have grown dramatically over the years through both internal innovation and acquisition. Success of their Continuous Improvement culture is based on margin growth and the effective integration of DBS into new acquisitions. The DBS uses a team-based kaizen approach to Continuous Improvement.

See Also

- Kaizen Philosophy: A Japanese philosophy that emphasizes continuous, incremental improvements in all aspects of an organization, involving all employees.

- Lean Manufacturing: A methodology focused on minimizing waste and maximizing value in operations, products, or services by optimizing resources, processes, and systems.

- Six Sigma: A data-driven methodology for process improvement that seeks to reduce variability and defects by identifying and eliminating the root causes of problems.

- Total Quality Management (TQM): A management approach that focuses on continuous improvement of all aspects of an organization to achieve customer satisfaction and operational excellence.

- Business Process Reengineering (BPR): The radical redesign and transformation of business processes to achieve significant improvements in cost, quality, service, and speed.

- Process Optimization: The act of refining and enhancing processes to improve efficiency, effectiveness, and overall performance.

- PDCA Cycle (Plan-Do-Check-Act): Cycle: A iterative four-step management method for continuous improvement, problem-solving, and quality control.

- DMAIC Framework: A structured, data-driven improvement methodology used in Six Sigma projects to optimize business processes.

- Value Stream Mapping: A lean-management technique used to analyze and visualize the flow of materials and information required to deliver a product or service to customers, with the goal of identifying waste and opportunities for improvement.

- Gemba Walk: A practice in which managers visit the work area (gemba) to observe processes, engage with employees, and identify opportunities for improvement.

References

- ↑ Definition - What Does Continuous Process Improvement (CPI) Mean? -Solve Xia

- ↑ Four continuous improvement models -Investors in People

- ↑ Six Core Principles of the Continuous Improvement Model -KaiNexus

- ↑ Steps to Continuous Process Improvement -Hinrichs Consulting

- ↑ Excellent Examples of Continuous Process Improvement (CPI) -Impruver