Supply Chain Management (SCM)

What is Supply Chain Management (SCM)?

Supply Chain Management (SCM) is an important framework that focuses on the cost, time, and quality of products through different operations, from supplier selection to manufacturing means and transportation and logistics modes (Ecer, 2020a).

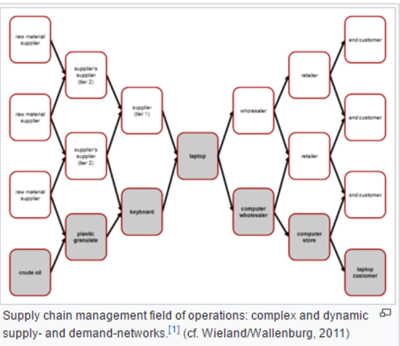

The concept of Supply Chain Management is based on two core ideas. The first is that practically every product that reaches an end user represents the cumulative effort of multiple organizations. These organizations are referred to collectively as the supply chain. The second idea is that while supply chains have existed for a long time, most organizations have only paid attention to what was happening within their “four walls.” Few businesses understood, much less managed, the entire chain of activities that ultimately delivered products to the final customer. The result was a disjointed and often ineffective supply chain. Supply chain management, then, is the active management of supply chain activities to maximize customer value and achieve sustainable competitive advantage. It represents a conscious effort by the supply chain firms to develop and run supply chains in the most effective & efficient ways possible. supply chain activities cover everything from product development, sourcing, production, and logistics, as well as the information systems needed to coordinate these activities. The organizations that make up the supply chain are “linked” together through physical flows and information flows. Physical flows involve the transformation, movement, and storage of goods and materials. They are the most visible piece of the supply chain. But just as important are information flows. Information flows allow the various supply chain partners to coordinate their long-term plans, and to control the day-to-day flow of goods and materials up and down the supply chain.[1]

source: Wikipedia

Supply chain management has evolved over the past 50 years to become a highly sophisticated, technology-dependent, and collaborative discipline that combines the business functions of purchasing, operations, inventory management and warehousing, customer service, and logistics. Operations and supply chain management is focused on managing the flow of goods, information, and cash while exceeding customer expectations at the lowest total cost possible. Supply chain management occurs globally in organizations and represents a strategic advantage for many companies. In a supply chain role, you will face challenges across operational, tactical, and strategic levels of business decisions.[2]

In his book, Future Logistics Challenges, Leif Enarsson of Sweden's Gothenburg University wonders why after all these years we still haven't arrived at a common definition of supply chain management...... Lambert, Cooper, and Pagh offered the following definition: "Supply chain management is the integration of key business processes from end user through original suppliers that provide products, services, and information that add value for customers and other stakeholders." That definition covers most business activities. Christopher's definition is more customer-focused: "The management of upstream and downstream relationships with suppliers and customers to deliver superior customer value at less cost to the supply chain as a whole."[3]

Supply Chain Management Technology[4]

If a company expects to achieve benefits from its supply chain management process, it will require some level of investment in technology. The backbone for many large companies has been the vastly expensive Enterprise Resource Planning (ERP) suites, such as SAP and Oracle. These enterprise software implementations will encompass a company’s entire supply chain, from purchasing raw materials to warranty service of items sold. The complexity of these applications does require a significant cost, not only a monetary cost but the time and resources required to successfully implement an enterprise-wide solution. Buy-in by senior management and adequate training of personnel is key to the success of the implementation. There are now many ERP solutions to choose from and it is important to select one which fits the overall needs of a company’s supply chain. Since the wide adoption of Internet technologies, all businesses can take advantage of Web-based software and Internet communications. Instant communication between vendors and customers allows for timely updates of information, which is key in the management of the supply chain.

Understanding the importance of SCM to its business, Walgreens Boots Alliance Inc. has placed a focused effort on transforming its supply chain in 2016. The company operates the second-largest pharmaceutical chain in the United States and needs to efficiently manage and revise its supply chain so it stays ahead of the changing trends and continues to add value to its bottom line. As of July 5, 2016, Walgreens has invested in the technology portion of its supply chain. It implemented a forward-looking SCM that synthesizes relevant data and uses analytics to forecast customer purchase behavior and then works its way back up the supply chain to meet that expected demand. For example, the company can anticipate flu patterns, which allows it to accurately forecast needed inventory for over-the-counter flu remedies, creating an efficient supply chain with little waste. Using this SCM, the company can reduce excess inventory and all of the inventories' associated costs, such as the cost of warehousing and transportation.[5]

Principles of Supply Chain Management (SCM)[6]

- Adapt Supply Chain to Customer's Needs: Both business people and supply chain professionals are trained to focus on the customer's needs. In order to understand the customer better, we divide customers into different groups and we call it "segmentation". The most primitive way to segment customers is ABC analysis which groups customers based on sales volume or profitability. Segmentation can also be done by product, industry, and trade channel. Back then, Anderson et al suggested that customers be segmented based on their service needs, namely, "sales and merchandising needs" and "order fulfillment needs". However, these days customers may not know what they need until the competition offers something different. For example, in 2011 Amazon initiated a program called Amazon Prime (free 2-day shipping and discounted 1-day shipping). Today, people are still discussing if this program makes sense. But one thing is for sure, the customer turns to Amazon more and more. The moral of this story is that you should "anticipate" the customer's needs as well.

- Customize Logistics Network: When you segment a customer based on the service needs, you may have to tailor the different logistics networks to serve different segments. However, this principle doesn't hold true for all situations. For example, if you were a contract manufacturer in China, you might already have different logistics networks for different customers. Each customer in US or EU might already control the source of raw materials, ask you to provide dedicated production lines and nominate 3rd Party Logistics (3PL) companies and air/sea carriers. So, logistics network design is a kind of initiative driven mainly by customers.

- Align Demand Planning Across Supply Chain: Supply chain practitioners are taught to share the demand data with trading partners so nobody has to keep unnecessary stock. In general, this principle holds true. But in the reality, only Walmart is actively sharing the demand data with trading partners. In the paper "Top-Down Versus Bottom-Up Demand Forecasts: The Value of Shared Point-of-Sale Data in the Retail Supply Chain" by Williams and Waller 2011, the result of research found that,

- If you make the demand forecast based on SKU/Customer level, using your own historical order data is more accurate than using the POS data you get from retailers

- If you make the demand forecast based on SKU/Store level, using the POS data you get from retailers is more accurate than using your own historical order data

The implication is that the absence of demand sharing is not necessarily bad. But when you got the demand data from trading partners, you MUST use it the right way.

- Differentiate Products Close to Customer: Dell keeps components and assembles them only after the customer places the order in order to increase the product variety. This principle is still true, but, there is another principle that should be considered. "Standardization" is in the opposite polarity of "Differentiation". For example, some cosmetics manufacturers formulate products and choose packaging and labeling that complies with the regulations of multiple countries in Asia. So they only make one SKU that can be sold in 15 countries instead of 1 SKU/Country. By standardizing products appropriately, they can drive the cost down drastically due to the economy of scale. So standardization is something that you should also consider.

- Outsource Strategically: This is the principle that stands the test of time. In short, don't ever outsource your core competency.

- Develop IT that Supports Multi-Level Decision Making: If you search Google for the term "critical success factor ERP", you'll find lots of information about how to implement ERP successfully. Therefore, an IT project shouldn't be done in the isolation, Business Process Reengineering (BPR) is something that you have to do before implementing an IT project. This will equip you with a full understanding of process deficiencies then you can determine what kind of technology you really need.

- Adopt Both Service and Financial Metrics: Anderson et al suggested that activity-based costing (ABC) be implemented so you can determine customer's profitability. However, there is an interesting twist to the ABC concept. In 1987, Robert Kaplan and W Bruns defined the activity-based costing concept in the book "Accounting and Management: A Field Study Perspective". However, in 2003 Robert Kaplan said that it's difficult to maintain an ABC costing model to reflect the changes in activities, processes, products, and customers. Then, he introduced the refined concept called "Time Driven Activity Based Costing".

Levels of Supply Chain Management(SCM)[7]

There are three levels of SCM: strategic, tactical, and operational.

- Strategic SCM deals with future planning than looking at market evaluation, capacity issues, new products, and technology changes. This planning is addressing issues that may be factors several years out. This is accomplished at the executive management level.

- Tactical SCM involves a shorter planning cycle. It is more concerned with demand planning, inventory planning, and supply planning. This is determined at a less senior level than Strategic SCM.

- Operational SCM is current planning activities measured in most weeks. Operational SCM involves the majority of the operations. It includes demand fulfillment, scheduling, production, transport, and monitoring.

Difference Between Logistics and Supply Chain Management[8]

The difference between logistics and supply chain management is as below: (see also figure below)

"Logistics typically refers to activities that occur within the boundaries of a single organization and supply chains refer to networks of companies that work together and coordinate their actions to deliver a product to market. Also, traditional logistics focuses its attention on activities such as procurement, distribution, maintenance, and inventory management. Supply Chain Management (SCM) acknowledges all of traditional logistics and also includes activities such as marketing, new product development, finance, and customer service" - from Essential of Supply Chain Management by Michael Hugos

source: Ben Benjabutr

Importance of Supply Chain Management[9]

It is well known that supply chain management is an integral part of most businesses and is essential to company success and customer satisfaction.

- Boost Customer Service: Customers expect the correct product assortment and quantity to be delivered. Customers expect products to be available at the right location. (i.e., customer satisfaction diminishes if an auto repair shop does not have the necessary parts in stock and can’t fix your car for an extra day or two).

- Right Delivery Time – Customers expect products to be delivered on time (i.e., customer satisfaction diminishes if pizza delivery is two hours late or Christmas presents are delivered on December 26).

- Right After Sale Support – Customers expect products to be serviced quickly. (i.e., customer satisfaction diminishes when a home furnace stops operating in the winter and repairs can’t be made for days)

- Reduce Operating Costs

- Decreases Purchasing Cost – Retailers depend on supply chains to quickly deliver expensive products to avoid holding costly inventories in stores any longer than necessary. For example, electronics stores require fast delivery of 60” flat-panel plasma HDTV’s to avoid high inventory costs.

- Decreases Production Cost – Manufacturers depend on supply chains to reliably deliver materials to assembly plants to avoid material shortages that would shut down production. For example, an unexpected parts shipment delay that causes an auto assembly plant shutdown can cost $20,000 per minute and millions of dollars per day in lost wages.

- Decreases Total Supply Chain Cost – Manufacturers and retailers depend on supply chain managers to design networks that meet customer service goals at the least total cost. Efficient supply chains enable a firm to be more competitive in the marketplace. For example, Dell’s revolutionary computer supply chain approach involved making each computer based on a specific customer order, then shipping the computer directly to the customer. As a result, Dell was able to avoid having large computer inventories sitting in warehouses and retail stores which saved millions of dollars. Also, Dell avoided carrying computer inventories that could become technologically obsolete as computer technology changed rapidly.

- Improve Financial Position

- Increases Profit Leverage – Firms value supply chain managers because they help control and reduce supply chain costs. This can result in dramatic increases in firm profits. For instance, U.S. consumers eat 2.7 billion packages of cereal annually, so decreasing U.S. cereal supply chain costs by just one cent per cereal box would result in $13 million dollars saved industry-wide as 13 billion boxes of cereal flowed through the improved supply chain over a five-year period.

- Decreases Fixed Assets – Firms value supply chain managers because they decrease the use of large fixed assets such as plants, warehouses, and transportation vehicles in the supply chain. If supply chain experts can redesign the network to properly serve U.S. customers from six warehouses rather than ten, the firm will avoid building four very expensive buildings.

- Increases Cash Flow – Firms value supply chain managers because they speed up product flows to customers. For example, if a firm can make and deliver a product to a customer in 10 days rather than 70 days, it can invoice the customer 60 days sooner.

- Societal Importance: Lesser known, is how supply chain management also plays a critical role in society. SCM knowledge and capabilities can be used to support medical missions, conduct disaster relief operations, and handle other types of emergencies. Whether dealing with day-to-day product flows or dealing with an unexpected natural disaster, supply chain experts roll up their sleeves and get busy. They diagnose problems, creatively work around disruptions, and figure out how to move essential products to people in need as efficiently as possible.

Challenges in Supply Chain Management[10]

Current supply chains are growing in complexity due to several factors. We, the customers, are demanding innovative products at the right time and at a reasonable price. This creates challenges for companies since creating both responsive and cost-effective supply chains is critically difficult. I find these challenges exciting and that’s why I decided to pursue a career in the field. Let me expand on today’s main supply chain challenges.

- Globalization: One of the biggest challenges that companies are facing is how to reduce their supply chain cost. In order to satisfy customers’ price expectations, companies have opted to relocate manufacturing to low-cost countries around the world in an effort to reduce direct and indirect costs and to minimize taxes. But, having global suppliers contributes significantly to the complexity that comes from extended delivery lead times. Customers not only want lower prices, but they also want their products on time.

- Customer Preferences: As stated above, global supply chains are complex. Add to that product features that are constantly changing, and the challenge is even greater. A product is released and customers rapidly pressure companies to come up with the next big thing. Innovation is important since it allows companies to stay competitive in the market, but it’s also a challenge. To enhance a product, companies have to redesign their supply network and meet market demand in a way that’s transparent for customers.

- Market Growth: Another factor that presents a challenge is the pursuit of new customers. The cost of developing a product, from R&D to product introduction, is significant. Therefore, companies are trying to expand their distribution to emerging markets in order to grow revenues and increase market share. Companies all around the world are expected to expand in their home and foreign markets. The introduction to new markets is difficult due to trading policies, fees, and government policies.

Customers’ expectations nowadays are more demanding than ever. As described here, companies have responded with global networks, product innovation, and market expansions. This means that companies now rely on supply chain managers to optimize their value chains in order to stay competitive. As such, it’s no surprise that these professionals are in high demand. So customers, rest assured - experts in supply chain management, including our own Grainger Center graduates - are behind the scenes tackling these complexities each and every day and are eager to delight the customer experience.

See Also

- Logistics Management

- Enterprise Resource Planning (ERP)

- Inventory Management

- Procurement

- Distribution Management

- Supplier Relationship Management

- Demand Forecasting

- Production Planning

- Warehouse Management

- Transportation Management

- Order Fulfillment

- Supply Chain Optimization

- Supply Chain Analytics

- Value Chain Analysis

- Operations Management

- Supply Chain Risk Management

References

- ↑ Understanding Supply Chain Management

- ↑ What is Supply Chain Management?

- ↑ What do we really mean by supply chain management?

- ↑ Supply Chain Management - The Need to Invest in Technology

- ↑ Example of SCM

- ↑ 7 Principles of Supply Chain Management-Ben Benjabutr

- ↑ The Three Levels of Supply Chain Management

- ↑ The Difference Between Logistics and Supply Chain Management

- ↑ The Importance of Supply Chain Management (SCM) -CSCMP

- ↑ The Challenges in Supply Chain Management

Further Reading

- Supply Chain Management

- A New Introduction to Supply Chains and Supply Chain Management: Definitions and Theories Perspective

- Evaluating Supply Chain Management: A Methodology Based on a Theoretical Model

- The impact of supply chain management practices on competitive advantage and organizational performance

- Artificial Intelligence: Transforming the phase of Supply Chain Management