Value Chain Analysis

Business Dictionary defines Value Chain analysis as an "Examination of the value chain of an enterprise to ascertain how much and at which stage value is added to its goods and/or services, and how it can be increased to enhance the product differentiation (competitive advantage)."[1]

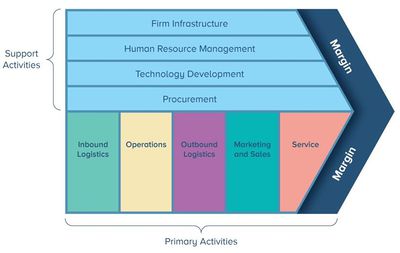

Value chain analysis focuses on analyzing the internal activities of a business in an effort to understand costs, locate the activities that add the most value, and differentiate from the competition. To develop an analysis, Porter's model outlines primary business functions as the basic areas and activities of inbound logistics, operations, outbound logistics, marketing and sales, and service. The model also identifies the discrete tasks found in the important support activities of firm infrastructure, human resources management, technology, and procurement. The overall goal of value chain analysis it to identify areas and activities that will benefit from change in order to improve profitability and efficiency. For more on Porter’s value chain model and a detailed description of the goals, functions, and tasks of a value chain, read The Art of Value Chain Analysis.[2]

The Formal Elements of Value Chain Analysis[3]

Porter built his value chain analysis model on a manufacturing business – back in 1985 there were many more around in the United States.

He split the value chain into two parts:

- 1. Primary value activities: Primary value activities included:

- Inbound logistics

- Operations

- Outbound logistics

- Marketing & sales

- Customer service

- 2. Support value activities: Support value activities include:

- Procurement

- Technology

- Human resources

- Firm infrastructure

Creating a Value Chain Analysis Chart[4]

A value chain analysis chart can be created in just a few simple steps.

- 1. Inbound logistics. The first step in value chain analysis is to examine inbound logistical items. Start with a column labeled "Inbound Logistics" and list and describe all of the systems and processes related to inbound logistics, such as purchasing systems, transportation, and other production and employee related activities that may be involved.

- 2. Operations. The second step is to analyze operations. Create a new column to the right of Logistics and label it "Operations." List and describe the various operational processes and systems from product development to the finished state. Items to consider may include raw materials and inventory, including how they are moved and handled.

- 3. Outbound logistics. Next, focus on outbound logistics. Begin a new column to the right and label it "Outbound Logistics." Consider the processes and systems involved in how the finished product ends up in the hands of customers and clients.

- 4. Sales and Marketing. Consider marketing activities and sales processes. Begin a new column, adjacent to the third with the label "Sales and Marketing." Record your analysis of the customer-purchasing experience and the post-purchase experience and activities.

- 5. Service. Look at the service-related activities of your business. In the fifth and final column, include analysis related to the various services provided by your business.

- 6. Underneath each of the columns you'll want to include the foundational activities of your business layered upon each other. In separate rows, include analysis that focuses on:

- Administration and Infrastructure

- Human Resources

- Product

- Technology and Development

- Procurement

- 7. Along the right side of the columns and rows, include a delta or triangle shape that focused on profit: "Value Added - Cost = Margin".

source: SmartSheet

Key Points of Value Chain Analysis[5]

Value Chain Analysis is a useful way of thinking through the ways in which you deliver value to your customers, and reviewing all of the things you can do to maximize that value. By using Value Chain Analysis and by following it through to action, you can achieve excellence in the things that really matter to your customers. Value Chain Analysis takes place as a three stage process:

- 1. Activity Analysis, where you identify the activities that contribute to the delivery of your product or service.

- 2. Value Analysis, where you identify the things that your customers value in the way you conduct each activity, and then work out the changes that are needed.

- 3. Evaluation and Planning, where you decide what changes to make and plan how you will make them.

Value Chain Analysis is a three-step process[6]

1. Analyze Activities: This step consists of identifying all key activities of a company that are involved in delivering the final product or service to its customers. A popular way to do this is to classify activities as either primary or support. Michael Porter identified five primary company activities:

- Inbound Logistics

- Operations

- Outbound Logistics

- Marketing and Sales

- Service

Primary activities are reinforced by support activities such as procurement, human resource development, technological development, and infrastructure. The list of activities and each activity classification may be adjusted by the company, as necessary. For example, inbound and outbound logistics may not be relevant for purely online businesses. After all activities are identified, the links between the activities need to be specified. For example, the service function, which supports customers, will have links to the operations function, which fulfills customer support requests, and the marketing and sales function, which analyzes customer feedback to improve offerings. The activities, together with the links between them, form the structure of the value chain.

2. Analyze Value Created by Those Activities: This step involves identifying where value is created throughout the chain, and in what form and magnitude. Value always needs to be explored from a customers point of view. A product feature or service component that does not benefit the customer does not add any value. Such an activity represents an opportunity for freeing up resources that could otherwise contribute to adding value through some other activity. For example, in a manufacturing environment, each manufacturing process that is involved in changing raw materials into finished product adds value by ensuring that the final product is functional. Quality assurance activities add value by ensuring that the products meet the standards required by customers. The sales teams efforts add value by encouraging more customers to purchase the products. The customer support activities add value by addressing customer questions and concerns and maintaining a high level of customer satisfaction.

3. Determine How to Create Additional Value: This step involves generating a number of ideas to add additional value to activities across the value chain and evaluating each of them to determine which are feasible and should be implemented. The various teams involved with the activities can hold brainstorming sessions to generate ideas for increasing the value of activities. Both improving an activity and lowering its costs can increase value. Thus, evaluating ideas for activity improvements should involve considering whether these actions represent a trade-off, or whether improving an activity and lowering its cost can be accomplished.

Uses of Value Chain Analysis[7]

- The sources of the competitive advantages of a firm can be seen from its discrete activities and how they interact with one another.

- The value chain is a tool for systematically examining the activities of a firm and how they interact with one another and affect each other's cost and performance.

- A form gains competitive advantage by performing these activities better or at lower cost than competitors.

- Helps you stay out of the "No Profit Zone".

- Presents opportunities for integration.

- Aligns spending with value processes.

Using the Value Chain Analysis tool[8]

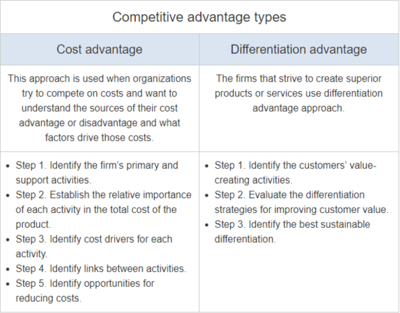

There are two different approaches on how to perform the analysis, which depend on what type of competitive advantage a company wants to create (cost or differentiation advantage). The table below lists all the steps needed to achieve cost or differentiation advantage using VCA.

source: Strategic Management Insight

- Cost advantage

To gain cost advantage a firm has to go through 5 analysis steps:

Step 1. Identify the firm’s primary and support activities. All the activities (from receiving and storing materials to marketing, selling and after sales support) that are undertaken to produce goods or services have to be clearly identified and separated from each other. This requires an adequate knowledge of company’s operations because value chain activities are not organized in the same way as the company itself. The managers who identify value chain activities have to look into how work is done to deliver customer value.

Step 2. Establish the relative importance of each activity in the total cost of the product. The total costs of producing a product or service must be broken down and assigned to each activity. Activity based costing is used to calculate costs for each process. Activities that are the major sources of cost or done inefficiently (when benchmarked against competitors) must be addressed first.

Step 3. Identify cost drivers for each activity. Only by understanding what factors drive the costs, managers can focus on improving them. Costs for labor-intensive activities will be driven by work hours, work speed, wage rate, etc. Different activities will have different cost drivers.

Step 4. Identify links between activities. Reduction of costs in one activity may lead to further cost reductions in subsequent activities. For example, fewer components in the product design may lead to less faulty parts and lower service costs. Therefore identifying the links between activities will lead to better understanding how cost improvements would affect he whole value chain. Sometimes, cost reductions in one activity lead to higher costs for other activities.

Step 5. Identify opportunities for reducing costs. When the company knows its inefficient activities and cost drivers, it can plan on how to improve them. Too high wage rates can be dealt with by increasing production speed, outsourcing jobs to low wage countries or installing more automated processes.

- Differentiation advantage

VCA is done differently when a firm competes on differentiation rather than costs. This is because the source of differentiation advantage comes from creating superior products, adding more features and satisfying varying customer needs, which results in higher cost structure.

Step 1. Identify the customers’ value-creating activities. After identifying all value chain activities, managers have to focus on those activities that contribute the most to creating customer value. For example, Apple products’ success mainly comes not from great product features (other companies have high-quality offerings too) but from successful marketing activities.

Step 2. Evaluate the differentiation strategies for improving customer value. Managers can use the following strategies to increase product differentiation and customer value:

- Add more product features;

- Focus on customer service and responsiveness;

- Increase customization;

- Offer complementary products.

Step 3. Identify the best sustainable differentiation. Usually, superior differentiation and customer value will be the result of many interrelated activities and strategies used. The best combination of them should be used to pursue sustainable differentiation advantage.

Application of Value Chain Analysis[9]

You can follow the following stages in order to conduct value chain analysis as a part of your assignment:

- Stage 1: Explaining the theory and the essence of value chain analysis: Write a brief introduction to the theory of value chain analysis. You may want to add the figure of value chain analysis (do not forget appropriate referencing). Inclusion of a brief discussion about advantages and disadvantages of the framework as mentioned above will contribute to your mark.

- Stage 2: Researching primary and support activities of your case study company: Value chain analysis can be applied in relation to a business unit, operating segment, business division or a company. If you have a choice, business unit is the most appropriate level for conducting value chain analysis from the practicality point of view. Some students prefer to choose their employer as a case study. However, student employers often happen to be small or medium sized business and it is difficult find necessary amount of relevant data to conduct value chain analysis in an appropriate manner. Selection]] of a multinational company is a more desirable scenario to be able to produce a quality value chain analysis due to the availability of needed company-specific data. Company annual report is the most comprehensive source of data and you can also find useful information on official website of the company. Alternatively, you can purchase company reports on major multinational enterprises form this portal. Reports comprise detailed value chain analyses of respective companies to be used as examples and template. Reports are kept updated regularly.

- Stage 3: Illustrating how each activity is facilitated by the case study company. This stage consists of two parts:

- Firstly, write about the manners in which the business conducts each activity. For example, for inbound logistics primary activity you can mention about the nature of raw materials the company uses and write about the numbers and location of suppliers. Similarly, when writing about operations primary activity you can discuss specific nature of company’s operations, as well as, numbers and locations of manufacturing units.

- Secondly, identify and discuss activities and sub-activities that create the most value for the company you are analyzing. This depends on the choice of cost advantage or differentiation business strategy by company. If the company benefits from cost advantage strategy, you have to specify which activities contribute the most to the achievement of cost leadership. In other words, you have to explain where the company saves the most cash and how.

Alternatively, if the company focuses on differentiation business strategy, you will need to find and discuss activities that the company has adapted as sources of its competitive advantage. Remember to justify each argument by referring to relevant statistical or non-statistical data from reliable sources. It has to be noted that there are also some general value adding strategies that can be used by businesses following both strategies – cost advantage AND differentiation. For example, Just-in-Time supply chain management system can be applied to create value in inbound logistics by businesses using cost leadership strategy, as well as, businesses using differentiation strategy with an equal level of efficiency.

Goals and outcomes of Value Chain Analysis[10]

Ideally, your value chain analysis will help your company identify areas that can be optimized for maximum efficiency and profitability. Ruth Campbell, senior vice president of technical learning and application at economic development nonprofit ACDI/VOCA told Business News Daily that the best result of a value chain analysis should be the identification of the following components:

- Key short- and medium-term end-market opportunities in the target value chains.

- Factors constraining the maximization of these opportunities (for small-scale producers, women, youth, etc.).

- Upgrading strategies to address these constraints and maximize opportunities.

- Private-sector, public-sector and civil society entities to partner with to achieve these upgrading strategies.

- Recommendations of how to support these value chain upgrading strategies in a way that is gender equitable, promotes improved nutrition (where relevant), and is inclusive of the poor and other marginalized group.

- At the other end of the spectrum, it's critical to properly understand and implement suggestions that arise as a result of a value chain analysis.

"One common misconception is that every constraint identified in a value chain analysis must be addressed," Campbell said. "Value chain analysis should be used to prioritize the most binding constraints — the ones that, if addressed, will produce the most beneficial impact — and/or those constraints that can be addressed relatively quickly and easily to produce momentum for change among value chain actors." Campbell also cautioned that if an analyst constructs your value chain analysis, it is up to you as the business owner or manager to make the most of his or her suggestions. "Social norms exert a huge influence in many contexts over what strategies are considered possible or acceptable," Campbell said. "A vision for VC development cannot be imposed by the analyst onto the local actors. Market actors have to embrace the vision if they are to invest their resources and change the way they do business." While value chain analysis is a tested and proven tool, other standards for analysis aim to embrace a business model that is not strictly business-to-consumer. Specifically, the Leveraging Economic Opportunities (LEO) Market Systems Framework aims to help companies that rapidly respond to changing market conditions and interface more broadly with household and communities than the traditional business assumed by value chain analysis. More information on this strategic analysis tool is available from USAID.

Advantages and Disadvantages of Value Chain Analysis[11]

There are many advantages of value chain analysis, which all result in a company's ability to understand and optimize the activities that lead to its competitive advantage and high profit levels. The disadvantage of value chain analysis is that it forces a company to break into segments, and there is the possibility of losing the big picture in the minutiae. The primary goal and advantage of a value chain, and therefore value chain analysis, is to create or strengthen a competitive advantage. Through analyzing the five primary value chain activities, a company can ensure that the value it's creating exceeds the cost to create that value. The five value chain activities are inbound logistics, operations, outbound logistics, marketing and sales, and service. If a company can create an advantage in any one of these activities through a value chain analysis, it captures a competitive advantage and increases its overall profit. To capture a competitive advantage, a company maps out its specific activities within the five generic value chain activities and looks for ways to create efficiencies. While there are many advantages of conducting a value chain analysis, the disadvantage of conducting this type of analysis is that sometimes a company's overall strategy and vision is lost when its operations are broken down into segments. While creating efficiencies in each of a company's value chain activities is important, the value chain doesn't do a good job of linking each activity in the chain together, and it's possible to lose sight of how the activities relate to each other.

Value Chain Analysis for Dell Inc.[12]

Dell Inc. was founded by Michael Dell in the early eighties. It is an American private multinational computer technology company that develops, sells, repairs and supports computers and other related products and services. It is currently one of the largest technological corporations in the world, containing more than 103,300 people worldwide. The company is well known for its innovations in supply chain management and electronic commerce, particularly its direct-sales model and its “configure to order” approach to manufacturing, which delivers individual PCs configured to the customer’s specifications. Dell was a pure hardware vendor for a long time, but when they acquired Perot Systems in 2009, they entered the market for IT services. Since then they have made additional acquisitions in storage and networking systems, with the purpose of expanding their portfolio from offering computers only to delivering complete solutions for their customers. In the last years they have faced some competition from other companies in the field, such as, HP, Apple, Toshiba, Sony, etc… Thankfully their build-to-order, sell direct value chain has proved successful over the years. In order for us to fully understand Dell’s direct value chain, we first need to understand what the value chain is. As stated by The Economic Times, “A value chain is the whole series of activities that create and build value at every step. The total value delivered by the company is the sum total of the value built up all throughout the company. Michael Porter developed this concept in his 1980 book Competitive Advantage.” According to Porter, a value chain is composed by primary activities and support activities. The Primary Activities involve, inbound logistics, which is basically getting the material in for adding value by processing it, operations, which are all the processes within the manufacturing, outbound, which involves distribution to the points of sale, marketing and sales, which is in charge of selling it branding it and promoting it, and service which maintains the functionality of the product, post sales. The Support Activities which reinforce all the primary ones, are the firm infrastructure, such as MIS, Human Resources, etc..

- PRIMARY ACTIVITIES

- INBOUND LOGISTICS: Dell Inc. has adopted Just-in-the-nick-of-time, for inbound logistics. The parts needed to assemble a PC are delivered by suppliers every couple of hours and double-decker conveyor belts serve each assembly point. They are aiming to reduce the inventory turnover time; the reason for this is the rapid advancements taking place in the computer components field. Their success in this matter can be proved with the fact that in 1998 their inventory turnover was seven days whereas the inventory turnover of the industry leader at that time, Compaq, was twenty three days.

- OPERATIONS: Until 97’ each worker performed a particular task in the assembly lines. However, after reorganization Dell shifted to “Cell Manufacturing” where a team of workers assembled the entire PC to consumer specification, then it was also dropped in favor of more improved assembly line. As consumer specifications vary for only some components, the company’s latest innovation is to pre-assemble a mixture of configurations that are commonly ordered.

- OUTBOUND LOGISTICS: After assembling the PC’s are transferred to the shipping department, where they are packed and shipped. The delivery of these PC’s takes three to five business days. The major output of the company is build to customer orders having a small inventory being produced to cater to the needs of retailers and whole sellers.

- MARKETING AND SALES: Dell sales are a mix of sell-direct-to-customer strategy and selling through retailers. They sells their products through their website, toll free lines and in case of corporate clients, etc… When the sell-direct-to-customer strategy failed they installed Kiosks in some electronic stores for the customer to physically check the product and then place an order. Unlike other manufactures Dell Inc.’s marketing efforts are focused towards the end users. Advertising is a major emphasis in the company; their strategy includes TV promotion, magazine ads, online promotion etc….

- SERVICE: The company has a lot of initiatives to provide after sale service and support to their customers. Some of these initiatives are premier pages, product design services, value-added services for customers and after sale services, etc…

- SUPPORT ACTIVITIES

- PRODUCT R&D, TECHNOLOGY AND SYSTEMS DEVELOPMENT: Dell Inc.’s R&D group employed four thousand engineers and had a budget of six hundred million dollars in 2008. They have high standards of quality control in it plants. They have various tests and quality control process to check the quality of parts, components, and finished products.

- PROCUREMENT: They work very closely with their suppliers to maintain the quality of their components. Their long term relationship with their suppliers has brought them some advantages, such as, the supply of enhanced quality components, the timely delivery of components, suppliers’ engineers are stationed at the company’s plants for development and launch of new products and also adapt new ways to reduce costs out of the supply chain.

- HUMAN RESOURCE MANAGEMENT: The company has 88,200 employees worldwide. 57% percent of these employees are in customer facing and frontline roles.

- GENERAL ADMINISTRATION: Dell Inc. has formed alliances with local service providers to provide on-site services to their customers. They have also formed strategic alliance with Lexmark to make printers and cartridges under the Dell label.

The Importance of Value Chain Analysis[13]

There are three main sets of reasons why value chain analysis is important in this era of rapid globalisation. They are:

- With the growing division of labour and the global dispersion of the production of components, systemic competitiveness has become increasingly important

- Efficiency in production is only a necessary condition for successfully penetrating global markets

- Entry into global markets which allows for sustained income growth – that is, making the best of globalisation - requires an understanding of dynamic factors within the whole value chain

See Also

- Value Chain

- Business Model: Overview of different types of business models and their components.

- Business Strategy:How business models align with and support overall business objectives.

- Value Proposition: The value a company promises to deliver to customers through its activities.

- Business Process Management (BPM): Methodologies for managing and improving business processes.

- Supply Chain Management (SCM): Managing the flow of goods and services, including all processes that transform raw materials into final products.

- Enterprise Architecture: Framework for aligning IT strategy with business strategy, often including business models and value chains.

- Business Architecture: The structure of a business, including its components, relationships, and processes.

- Strategic Planning: The process of defining strategy and making decisions on allocating resources to pursue this strategy.

- IT Governance: Framework ensuring IT supports and enables the business model and overall strategy.

- Digital Transformation (DX): The integration of digital technology into all areas of a business, fundamentally changing how it operates and delivers value.

- Process Improvement: Techniques and methodologies for improving business processes.

- Innovation Management: Managing processes involved in the innovation of business models and practices.

References

- ↑ Definition of Value Chain Analysis Business Dictionary

- ↑ What is Value Chain Analysis (VCA)? SmartSheet

- ↑ What are the Formal Elements of Value Chain Analysis? Paul Simister

- ↑ How to Create a Value Chain Analysis Chart? SmartDraw

- ↑ Key Points of Value Chain Analysis Mind Tools

- ↑ Value Chain Analysis is a three-step process' SM Study

- ↑ Uses of Value Chain Analysis Mohnish rm

- ↑ Using the Value Chain Analysis tool Strategic Management Insight

- ↑ Application of Value Chain Analysis Research Methodology

- ↑ Goals and outcomes of Value Chain Analysis Business News Daily

- ↑ What are some advantages and disadvantages of value chain analysis? Investopedia

- ↑ Value Chain Analysis for Dell Inc. ANGELLYELIAS

- ↑ Why is value chain analysis important? IDRC

Further Reading

- The Importance and relevance of utilising Value Chain analysis in strategic decision making Darnel Greenidge

- Use Value Chain Analysis for Customer Satisfaction Betty Feng

- Value Chain Analysis and Competitive Advantage Prescott C. Ensign

- Electronic and Print Journals: A Value Chain Analysis NOPR