The Bullwhip Effect

What is The Bullwhip Effect?

The Bullwhip Effect (or the Forrester Effect) is defined as the demand distortion that travels upstream in the supply chain due to the variance of orders which may be larger than that of sales, or the presence of too many echelons in the supply chain (Lee and Billington, 1992). The bullwhip effect occurs when the demand order variabilities in the supply chain are amplified as they move up the chain. The concept is created to help supply chain professionals effectively counteract the bullwhip effect.[1]

The concept first appeared in Jay Forrester's Industrial Dynamics (1961) and thus it is also known as the Forrester effect. The bullwhip effect was named for the way the amplitude of a whip increases down its length. The further from the originating signal, the greater the distortion of the wave pattern. In a similar manner, forecast accuracy decreases as one moves upstream along the supply chain. For example, many consumer goods have fairly consistent consumption at retail. But this signal becomes more chaotic and unpredictable as you move away from consumer purchasing behavior. In the 1990s, Hau Lee, a Professor of Engineering and Management Science at Stanford University, helped incorporate the concept into supply chain vernacular using a story about Volvo. Suffering a glut in green cars, sales and marketing developed a program to move the excess inventory. While successful in generating the desired market pull, manufacturing did not know about the promotional plans. Instead, they read the increase in sales as an indication of growing demand for green cars and ramped up production.[2]

Causes of the Bullwhip Effect[3]

- Forecasting Errors: When companies enter new products into the marketplace, they estimate the demand for the good based on current market conditions. Most companies in the supply order more than they can sell, attempting to prevent shortages and lost sales of goods. This "extra" inventory begins to increase or decrease during the normal market fluctuations of supply and demand. When demand increases, the companies closest to the consumer will increase inventory to meet the consumer demand. When the demand falls, the front end of the supply chain will decrease inventory, amplifying the extra inventory on each company up the supply chain.

- Behavioral Causes: One cause of the bullwhip effect is normally driven by management behavior at the front-end companies of the supply chain. Retail management never wants to have a stock-out on a popular good, leading to higher orders from the wholesalers. This eventually squeezes each company in the supply chain and creates decreases in inventory.

- Another major behavioral effect is the ordering of too much inventory when consumer demand has fallen for an item. Retailers may have raised their inventory levels to avoid a stock-out but are now met with goods that cannot be sold quickly. This creates an overstock of inventory for each supply chain company.

- Operational Causes: The main operational cause of the bullwhip effect comes from individual demand forecasts from each company in the supply chain. This causes an increase in demand from companies in the supply chain, but not the actual consumers who will purchase the goods. A lack of communication is also prevalent during operational causes; companies may not supply information up the supply chain regarding current market conditions, causing improper levels of inventory.

Example of the Bullwhip Effect[4]

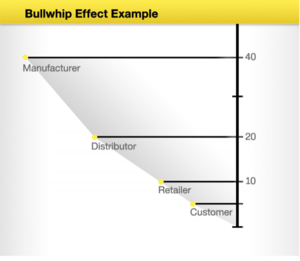

Let’s look at an example; the actual demand for a product and its materials starts at the customer, however often the actual demand for a product gets distorted going down the supply chain. Let’s say that an actual demand from a customer is 8 units, the retailer may then order 10 units from the distributor; an extra 2 units are to ensure they don’t run out of floor stock.

The supplier then orders 20 units from the manufacturer; allowing them to buy in bulk so they have enough stock to guarantee the timely shipment of goods to the retailer. The manufacturer then receives the order and then orders from their supplier in bulk; ordering 40 units to ensure economy of scale in production to meet demand. Now 40 units have been produced for a demand of only 8 units; meaning the retailer will have to increase demand by dropping prices or finding more customers by marketing and advertising. Although the bullwhip effect is a common problem for supply chain management understanding the causes of the bullwhip effect can help managers find strategies to alleviate the effect.

Countermeasures to the Bullwhip Effect[5]

While the bullwhip effect is a common problem, many leading companies have been able to apply countermeasures to overcome it. Here are some of these solutions:

- Countermeasures to order batching - High order cost is countered with Electronic Data Interchange (EDI) and computer-aided ordering (CAO). Full truckload economics are countered with third-party logistics and assorted truckloads. Random or correlated ordering is countered with regular delivery appointments. More frequent ordering results in smaller orders and smaller variances. However, when an entity orders more often, it will not see a reduction in its own demand variance - the reduction is seen by the upstream entities. Also, when an entity orders more frequently, its required safety stock may increase or decrease; see the standard loss function in the Inventory Management section.

- Countermeasures to shortage gaming - Proportional rationing schemes are countered by allocating units based on past sales. Ignorance of supply chain conditions can be addressed by sharing capacity and supply information. Unrestricted ordering capability can be addressed by reducing the order size flexibility and implementing capacity reservations. For example, one can reserve a fixed quantity for a given year and specify the quantity of each order shortly before it is needed, as long as the sum of the order quantities equals the reserved quantity.

- Countermeasures to fluctuating prices - High-low pricing can be replaced with everyday low prices (EDLP). Special purchase contracts can be implemented in order to specify ordering at regular intervals to better synchronize delivery and purchase.

- Countermeasures to demand forecast inaccuracies - Lack of demand visibility can be addressed by providing access to point of sale (POS) data. Single control of replenishment or Vendor Managed Inventory (VMI) can overcome exaggerated demand forecasts. Long lead times should be reduced where economically advantageous.

- Free return policies are not addressed easily. Often, such policies simply must be prohibited or limited.

See Also

Vendor Managed Inventory (VMI)

References