Industry 4.0

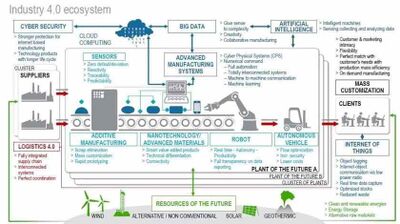

Industry 4.0 is signaling a change in the traditional manufacturing landscape. Also known as the Fourth Industrial Revolution, Industry 4.0 encompasses three technological trends driving this transformation: connectivity, intelligence and flexible automation. Industry 4.0 converges IT (Information Technology) and OT (Operational Technology), to create a cyber-physical environment. This convergence has been made possible thanks to the emergence of digital solutions and advanced technologies, which are often associated with Industry 4.0.[1]

Industry 4.0 and the Fourth Industrial Revolution (4IR)[2]

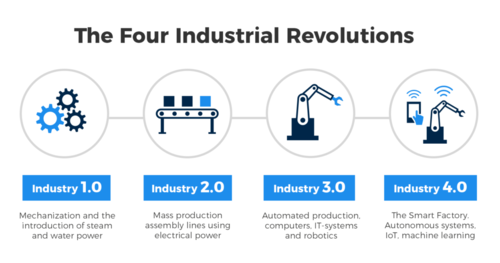

The classic view of these four industrial revolutions, as Industry 4.0 became increasingly popular, was:

- The first industrial revolution, which REALLY was a revolution, and, among others thanks to invention of steam machines, the usage of water and steam power and all sorts of other machines, would lead to the industrial transformation of society with trains, mechanization of manufacturing and loads of smog.

- The second industrial revolution is typically seen as the period where electricity and new manufacturing ‘inventions’ which it enabled, such as the assembly line, led to the area of mass production and to some extent to automation.

- The third industrial revolution had everything to do with the rise of computers, computer networks (WAN, LAN, MAN,…), the rise of robotics in manufacturing, connectivity and obviously the birth of the Internet, that big game changer in the ways information is handled and shared, and the evolutions to e-anything versions of previously brick and mortar environments only, with far more automation.

- In the fourth industrial revolution we move from ‘just’ the Internet and the client-server architecture to ubiquitous mobility, the bridging of digital and physical environments (in manufacturing referred to as Cyber Physical Systems), the convergence of IT and OT, and all the previously mentioned technologies (Internet of Things, Big Data, cloud, etc.) with additional accelerators such as advanced robotics and AI/cognitive which enable Industry 4.0 with automation and optimization in entirely new ways that lead to ample opportunities to innovate and truly fully automate and bring the industry to the next level. Some also like to add the injection of technology and connectivity in the human/digital mind and body convergence to Industry 4.0

source: Spectral Engines

Characteristics of Industry 4.0[3]

- Vertical Networking: Digital-to-physical processes enable manufacturers to rapidly respond to various changes that come as result of shifting demands, stock levels or unexpected equipment faults. Smart factories are highly connected entities, with different systems being able to interact with one another and adjust their performance.

- Horizontal integration via a new generation of global value chain networks: The physical-digital-physical (PDP) loops enable a higher level of transparency. Companies can locate and respond to problems faster. Such organization-wide networks can record information from all the operations including intralogistics and warehousing, to prototyping and production, to marketing and sales to downstream services. Every aspect of every process is logged and can be assessed and analyzed at any time.

- Through-engineering across the entire value chain: All the product development and manufacturing activities are integrated and coordinated with the product life cycles. New synergies emerge between product development and production systems.

- Acceleration through exponential technologies: One of the pillars of Industry 4.0 is creating an increasingly autonomous and highly cognitive ecosystem. It relies on technologies such as machine learning, deep learning, advanced robotics and industrial IoT to further accelerate efficiency.

Technologies Driving Industry 4.0[4]

- Internet of Things (IoT): The Internet of Things (IoT) is a key component of smart factories. Machines on the factory floor are equipped with sensors that feature an IP address that allows the machines to connect with other web-enabled devices. This connectivity makes it possible for large amounts of valuable data to be collected, analyzed and exchanged.

- Cloud Computing: Cloud computing is a cornerstone of any Industry 4.0 strategy. Full realization of smart manufacturing demands connectivity and integration of engineering, supply chain, production, sales and distribution, and service. Cloud helps make that possible. In addition, the typically large amount of data being stored and analyzed can be processed more efficiently and cost-effectively with cloud. Cloud computing can also reduce startup costs for small- and medium-sized manufacturers who can right-size their needs and scale as their business grows.

- AI and Machine Learning: AI and machine learning allow manufacturing companies to take full advantage of the volume of information generated not just on the factory floor, but across their business units, and even from partners and third-party sources. AI and machine learning can create insights providing visibility, predictability and automation of operations and business processes. For instance: Industrial machines are prone to breaking down during the production process. Using data collected from these assets can help businesses perform predictive maintenance based on machine learning algorithms, resulting in more uptime and higher efficiency.

- Edge Computing: The demands of real-time production operations mean that some data analysis must be done at the “edge”—that is, where the data is created. This minimizes latency time from when data is produced to when a response is required. For instance, the detection of a safety or quality issue may require near-real-time action with the equipment. The time needed to send data to the enterprise cloud and then back to the factory floor may be too lengthy and depends on the reliability of the network. Using edge computing also means that data stays near its source, reducing security risks.

- Cybersecurity: Manufacturing companies have not always considered the importance of cybersecurity. However, the same connectivity of operational equipment in the factory or field (OT) that enables more efficient manufacturing processes also exposes new entry paths for malicious attacks and malware. When undergoing a digital transformation to Industry 4.0, it is essential to consider a cybersecurity approach that encompasses IT and OT equipment.

- Digital Twin: The digital transformation offered by Industry 4.0 has allowed manufacturers to create digital twins that are virtual replicas of processes, production lines, factories and supply chains. A digital twin is created by pulling data from IoT sensors, devices, PLCs and other objects connected to the internet. Manufacturers can use digital twins to help increase productivity, improve workflows and design new products. By simulating a production process, for example, manufacturers can test changes to the process to find ways to minimize downtime or improve capacity.

source: Supply Chain GameChanger

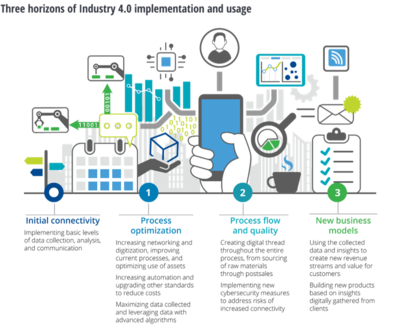

Three Horizons of Industry 4.0[5]

Manufacturers seeking entry into an integrated system require a basic level of connectivity. Once this connectivity is established, they can begin the journey toward integrating digitalization processes. This typically occurs in three different horizons: process optimization, process flow and quality, and new business models (see figure below).

- Process Optimization: In this phase, companies look inward to improve current processes. Initiatives in this phase typically target a specific need and have a clearly visible ROI. These types of activities can represent the easiest step for organizations to take, as they represent cost savings, rather than the uncertainty of new processes. For example, solutions in this horizon include predictive maintenance of machinery and utilization of data for production process improvements. This generally requires a basic level of connectivity to enable data collection and analysis; however, it can be limited in scope. Thus, these solutions tend to be easier to implement as they represent a limited number of technologies targeting a specific issue. Further, they generally do not face as many of the organizational challenges or technological barriers that can arise when organizations try to link multiple different legacy systems in larger, cross-functional initiatives.

- Process Flow and Quality: Companies working on the second horizon increase their level of connectivity to improve process flow and upgrade quality. In this phase, organizations can seek to evolve their supply chains toward digital supply networks, in which information flows throughout all stages of the interconnected value chain, enabling greater responsiveness and more informed decision-making. For instance, sales data can be collected and analyzed, then automatically transferred to sourcing and manufacturing systems; suppliers can more effectively connect to manufacturers’ systems for dynamic responses to shifts in supply and demand. Unlike the first horizon, more technological and organizational shifts are generally required, as well as a more critical imperative for systemwide connectivity. Further, benefits can take longer to realize, and can come with significant upfront investments.

- New Business Models. In the third horizon, new business models are created. This can consist of new products, increased product personalization, or entirely new revenue models. For example, driven by strong demand from clients, many original equipment manufacturers (OEMs) are adding smart equipment into their portfolio, and some are even attempting to use these products to pivot from being a supplier to a service provider. While a great deal of companies can agree that truly transformative value lies in this horizon, many still struggle to formulate how to successfully realize an effective model.

It is important to note that while these horizons tend to be progressive, they are not mutually exclusive; companies that have progressed to the second horizon can also have activities in the first horizon. Regardless of the mode of the implementation and the horizon in which initiatives fall, Industry 4.0 can have a strong impact, potentially boosting several performance indicators, including lower maintenance costs, decreased downtime, savings in inventory costs, gains in labor productivity, accelerated production time, and savings related to improved ability to predict outcomes. One executive interviewed noted that, by adopting sensors and adaptive control technology, his organization was able to reduce cycle times by 30 percent. When it comes to implementing Industry 4.0 within these three horizons, manufacturers and suppliers seek the right technologies in which to invest, to obtain these types of benefits. Given their tangible results, initiatives with a clear link to ROI—or the first horizon, process optimization—have typically been easier for manufacturers to adopt. And, in fact, research has shown that operations and processes are the top areas for focus for Industry 4.0 initiatives.

Design Principles and Primary Drivers of Industry 4.0[6]

There are four design principles identified as integral to Industry 4.0:

- Interconnection — the ability of machines, devices, sensors, and people to connect and communicate with each other via the Internet of things, or the internet of people (IoP)

- Information transparency — the transparency afforded by Industry 4.0 technology provides operators with comprehensive information to make decisions. Inter-connectivity allows operators to collect immense amounts of data and information from all points in the manufacturing process, identify key areas that can benefit from improvement to increase functionality

- Technical assistance — the technological facility of systems to assist humans in decision-making and problem-solving, and the ability to help humans with difficult or unsafe tasks

- Decentralized decisions — the ability of cyber physical systems to make decisions on their own and to perform their tasks as autonomously as possible. Only in the case of exceptions, interference, or conflicting goals, are tasks delegated to a higher level

The Primary Drivers include:

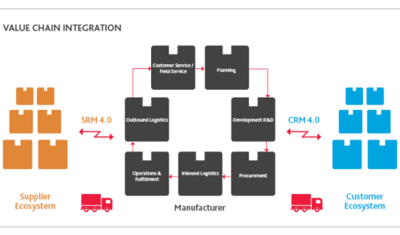

- Digitization and integration of vertical and horizontal value chains — Industry 4.0 integrates processes vertically, across the entire organization, including processes in product development, manufacturing, structuring, and service; horizontally, Industry 4.0 includes internal operations from suppliers to customers as well as all key value chain partners.

- Digitization of product and services — integrating new methods of data collection and analysis–such as through the expansion of existing products or creation of new digitized products–helps companies to generate data on product use in order to refine products

- Digital business models and customer access — customer satisfaction is a perpetual, multi-stage process that requires modification in real-time to adapt to the changing needs of consumers

Is Industry 4.0 Right for You?[7]

How do you know when or if your business should invest in Industry 4.0? If you’re able to check off most of the items on this list, it’s probably safe to start evaluating Industry 4.0 technology and solution providers and allocating the resources needed for deployment:

- You are in a particularly competitive industry with a lot of tech-savvy players

- You are having a hard time recruiting to fill vacant jobs at your organization

- You want better visibility across your supply chain

- You want to identify and address issues before they become bigger problems

- You want to boost efficiency and profitability across your entire organization

- You want everyone on your team to have informed, up-to-date, relevant views of production and business processes

- You want richer and more timely analytics

- You need help digitizing and making sense of information

- You want to improve customer satisfaction and customer experience

- You want to improve product quality or keep product quality intact

- You want a more integrated enterprise resource planning system that spans not only inventory and planning, but also financials, customer relationships, supply chain management, and manufacturing execution

- You want a consistent and flexible view of production and business operations tailored to specific areas or users in your organization

- You want real-time insights that help you make better, faster decisions about your business each day

The Worth of Industry 4.0[8]

Anything attached to the Internet of Things or increased automation is worth a tidy sum and Industry 4.0 is no different, with analysis valuing the technology around the idea as practically never-ending. Recent figures from KPMG has estimated that the component markets of Industry 4.0 are estimated to be worth more than US$4 trillion by 2020. This is above the expected value of the Internet of Things (IoT) market, which Gartner has estimated will be worth almost US$3.7 trillion by 2020.

Businesses everywhere are thought to be able to benefit from embracing Industry 4.0, with a recent government report claiming that utilizing this advanced technology could benefit the nation's manufacturing sector by around £445 billion and create around 175,000 jobs. Much of this is down to the thirst for higher productivity and cost reductions from using real-time data. This can also be another area where technologies of the future, such as 5G, will have an effect and make sure the "things" are buzzing away at optimum efficiency.

Whatever the cost, the value of Industry 4.0 comes from improving productivity and removing inefficiency at all levels, making it one of the most valuable ideas of our time.

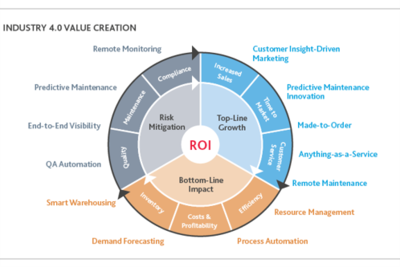

Industry 4.0 Equals Value Creation[9]

You don’t need to be a tech whiz to turn the Industry 4.0 phenomenon to your advantage. The opportunity boils down to three areas of potential value creation: bottom-line impact, top-line growth and risk mitigation.

While value is created in different ways depending on where you are on the maturity continuum, incremental value is available to every manufacturer—but it must be rooted in incremental improvements to your current capabilities. It can start with a single improvement initiative in a single functional area. Even small, functional change has ripple effects throughout the entire enterprise. These single, incremental improvements should ultimately be performed against the backdrop of your overarching Industry 4.0 vision, strategy and roadmap to drive tangible ROI enterprise-wide. The key is to flip your thinking. Instead of focusing on specific technology features or tools, let your goals for value creation lead the way. The real goal for your business isn’t, for example, to have predictive maintenance capabilities; it’s for that predictive maintenance investment to reduce your mean time between failures, optimize return on invested capital and ultimately preserve or enhance asset value. Start with your high-level objective—whether it’s higher levels of performance agility, better inventory turnover or a reduction in production errors— and work backwards from there, asking the question, “How will information transparency, availability and automation unlock business value to this capability?”

Keep in mind that value creation opportunities will also evolve as you progress in Industry 4.0 maturity. Digitization can fundamentally change the nature of your relationships with suppliers and customers, fostering collaboration and breaking down traditional barriers. The linear supply chain will morph into an integrated value chain of mutually beneficial relationships where suppliers and customers collaborate to achieve efficiencies and lower costs by exchanging information and securely integrating systems and processes.

The integrated value chain is predicated on a new level of transparency and information sharing, including constant, bidirectional communication and inter-company visibility into everything from inventory condition, supply status and shipping delays to future-focused factors predicting shifts in demand. This flow of information and aggregated business intelligence across the supply network is often referred to as the digital thread, the lifeblood of Industry 4.0.

The real value of the digital thread comes from enabling faster speed to market and speed to decision, empowered by access to more relevant and timely information, enabling better business intelligence and greater intimacy with supplier performance and customer behavior. This sets you up for synergistic co-creation of value, where savings and opportunities are generated and shared between business partner organizations, resulting in “win/win/win” relationships.

Benefits and Challenges in Adopting an Industry 4.0 Model[10]

Benefits

Similar to digital transformation, the benefits of Industry 4.0 will ultimately help a business become smarter and more efficient. To summarise, here are the key benefits of the new industrial revolution…

- Enhanced productivity through optimisation and automation

- Real-time data for real-time supply chains in a real-time economy

- Greater business continuity through advanced maintenance and monitoring possibilities

- Higher quality products as a result of real-time monitoring, IoT-enabled quality improvement and cobots

- Better working conditions and superior sustainability

- Personalisation opportunities that will earn the trust and loyalty the modern consumer

Challenges

As Industry 4.0 continues to change the way we interact with the world around us, new challenges arise. Here are the main challenges you may face in the not so distant future:

- New business models — the definition of a new strategy

- Rethinking your organization and processes to maximise new outcomes

- Understanding your business case

- Conducting successful pilots

- Helping your organization to understand where action is needed

- Change management, something that is too often overlooked

- Examination of company culture

- The genuine interconnection of all departments

- Recruiting and developing new talent

The Internet of Things (IoT) will connect machines and systems and allow seamless data transmission across all departments of a workplace, opening up opportunities for entirely new business models in manufacturing, computing, and many other industries. Talking to the Strait Times about the manufacturing sector, IoT expert Dr Gunther Kegel explained, “A device originally used for simple protection can now provide data, which can, for instance, be sold to insurance companies. All of a sudden, your business model is completely different.”

To thrive and indeed survive in tomorrow’s world, you will need to look at each of the above challenges and act upon them as soon as possible. But, it’s important to remember that above all, Industry 4.0 requires businesses and organizations to adopt a fresh thinking mindset, understanding the power of the inter-connectivity realized by new technologies. By being able to adopt a new mindset, refresh your company culture, adapt your business model, create new roles and nurture the talent to fulfil those roles, the rest will follow, as long as your change is managed closely throughout the process.

Next - Industry 5.0[11]

Industry 5.0 is already being spoken about and involves robots and smart machines allowing humans to work better and smarter.

Esben Østergaard, Universal Robots chief technology officer and co-founder, explained, “Industry 5.0 will make the factory a place where creative people can come and work, to create a more personalized and human experience for workers and their customers."

By connecting the way in which man and machine work together, estimates say that Industry 5.0 will mean that over 60% of manufacturing, logistics and supply chains, agri-farming, and the mining and oil and gas sectors will employ chief robotics officers by 2025.

The European Economic Social Committee asserts that, "The proliferation of robotic automation is inevitable.”

See Also

References

- ↑ Defining Industry 4.0 AMFG

- ↑ Industry 4.0 and the Fourth Industrial Revolution (4IR) i-scoop.eu

- ↑ Four Main Characteristics of Industry 4.0 Infopulse

- ↑ What technologies are driving Industry 4.0? IBM

- ↑ The Three Horizons of Industry 4.0 Deloitte Insights

- ↑ Design Principles and Primary Drivers of Industry 4.0 Wikipedia

- ↑ Who Is Industry 4.0 Right For? Epicor

- ↑ How much is Industry 4.0 worth? Techradar

- ↑ Industry 4.0 = Value Creation BDO

- ↑ Benefits and Challenges in Adopting an Industry 4.0 Model IIOT World

- ↑ What are the Details of Industry 5.0? TWI- Global